If you need any help, please feel free to contact us

What are the main differences between JGS1, JGS2, and JGS3 materials?

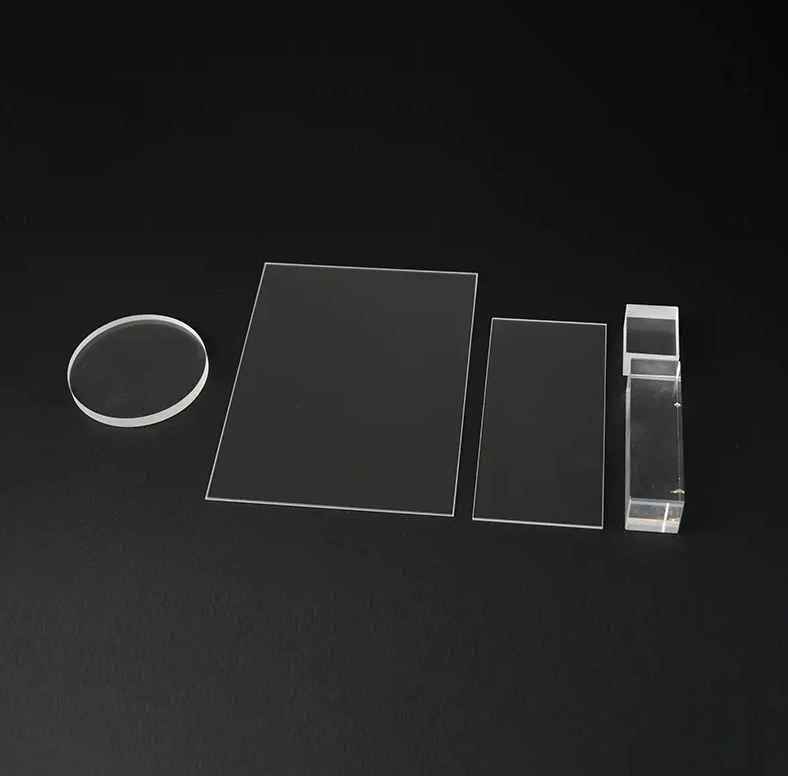

In the high-performance glass market, Quartz Glass Plate, with their superior physical and chemical properties, have become important materials for high-tech industries such as semiconductors, optics, lasers, and aerospace.

Content

What is a quartz glass plate?

A quartz glass plate is a special industrial technical glass made of pure silicon dioxide ($SiO_2$). It not only has an extremely low thermal expansion coefficient and extremely high temperature resistance, but also boasts a wide spectral transmittance from ultraviolet to infrared. Based on its optical characteristics and manufacturing process, it is usually classified into three main grades internationally: JGS1, JGS2, and JGS3.

JGS1: Far Ultraviolet Optical Quartz Glass

JGS1 is the highest purity quartz material with the best optical performance, usually produced by vapor phase synthesis (flame hydrolysis method).

Core characteristics: Extremely high transmittance in the ultraviolet band (especially 185nm-250nm).

Optical advantages: No internal bubbles, extremely low striations, and free of any metal impurities.

Applications: Commonly used in the manufacture of high-precision lenses, quartz glass windows, observation windows for UV sterilization equipment, laser scanning systems, and precision optical instruments.

JGS2: Ultraviolet Optical Quartz Glass

JGS2 is the most widely used quartz glass plate material, usually melted from natural high-quality crystal powder using the gas melting method.

Core characteristics: Excellent performance in the visible and near-ultraviolet bands, but its transmittance in the far-ultraviolet region (<200nm) is slightly lower than JGS1.

Cost-effectiveness advantage: Compared to JGS1, its production cost is more competitive, while retaining the excellent heat resistance and chemical stability of quartz glass.

Applications: Widely used in laboratory high-temperature sight glasses, industrial observation windows, UV curing equipment, and general vacuum windows.

JGS3: Infrared Optical Quartz Glass

JGS3 is also known as "hydroxyl-free quartz glass," and it is produced by the electric melting method in a vacuum environment.

Core characteristics: Excellent transmittance in the infrared band, its biggest feature being extremely low hydroxyl (-OH) content (usually less than 2 ppm). This effectively eliminates the absorption peak in the infrared spectrum at 2.73 μm.

Technical Specifications: Maintains extremely high transmittance in the infrared band of 2600nm-3500nm.

Applicable Scenarios: It is the ideal quartz glass plate material for infrared thermometers, infrared sensors, optoelectronic instrument windows, and thermal radiation detection equipment.

Comparison of the Three:

1. JGS1: Far Ultraviolet Optical Quartz Glass (Synthetic Quartz)

JGS1 represents the highest standard in optical purity for Quartz Glass Plate, especially suitable for applications with extremely high requirements for short-wave ultraviolet light.

Manufacturing Process: Made from high-purity silicon tetrachloride as raw material, using a gas-phase synthesis method through hydrogen-oxygen flame hydrolysis.

Spectral Performance: Excellent performance in the far ultraviolet band, with a transmittance of over 90% at 185nm, and no significant absorption bands in the 185-2500nm range.

Key Parameters: High hydroxyl (-OH) content, usually between 1000-2000ppm.

Core Applications: It is the core quartz glass plate material for manufacturing ultraviolet lasers, precision optical lenses, analytical instrument spectrometers, and semiconductor photomasks.

2. JGS2: Ultraviolet Optical Quartz Glass (Flame-Fused Quartz)

JGS2 is currently the most widely used quartz glass plate in industrial applications. While maintaining excellent physical properties, it offers extremely high cost-effectiveness.

Manufacturing Process: Made from high-quality natural crystal or high-purity quartz sand as raw materials, melted by the hydrogen-oxygen flame fusion method.

Spectral Performance: Transmittance range covers 220-2500nm. Although its performance in the deep ultraviolet region is slightly inferior to JGS1, it has excellent transparency in the visible and near-infrared regions.

Key Parameters: Moderate hydroxyl content, generally controlled at 150-200ppm.

Core Applications: Widely used in high-temperature observation windows, laboratory glassware, ultraviolet curing lamp covers, and general industrial-grade quartz glass plate windows.

3. JGS3: Infrared Optical Quartz Glass (Electrically Fused Quartz)

JGS3 is a quartz glass plate specifically designed for infrared technology. Its greatest technological breakthrough lies in completely solving the problem of infrared absorption interference.

Production Process: Made from natural high-purity quartz sand, melted at high temperature in a vacuum electric furnace.

Spectral Performance: Exhibits extremely high transmittance in the 260-3500nm range. Its most significant feature is the virtual absence of absorption peaks near 2.73μm, ensuring accurate transmission of infrared signals.

Key Parameters: It is an ultra-low hydroxyl material, with an -OH content typically below 2ppm (and can even reach <1ppm).

Core Applications: Ideal for infrared thermometer windows, thermal imaging systems, infrared light source protective plates, and photoelectric detection equipment.

How to Choose the Right Quartz Glass Plate?

As a professional Quartz Glass Plate manufacturer, we recommend following these principles when purchasing:

Clearly define the working wavelength range: If ultraviolet operation below 200nm is involved, be sure to choose JGS1.

Consider the impact of hydroxyl groups: If used for infrared spectroscopy or temperature measurement, low-hydroxyl JGS3 must be selected to avoid absorption interference.

Balance budget and performance: For applications where extreme spectral requirements are not necessary, JGS2 is a very cost-effective option.

If you have special requirements for the tolerance, coating, or temperature resistance of the quartz glass plate, please contact us. We can provide customized processing solutions for you.

+86-0515-86223369

+86-0515-86223369  en

en English

English 日本語

日本語 Español

Español