If you need any help, please feel free to contact us

Web Menu

Product Search

Exit Menu

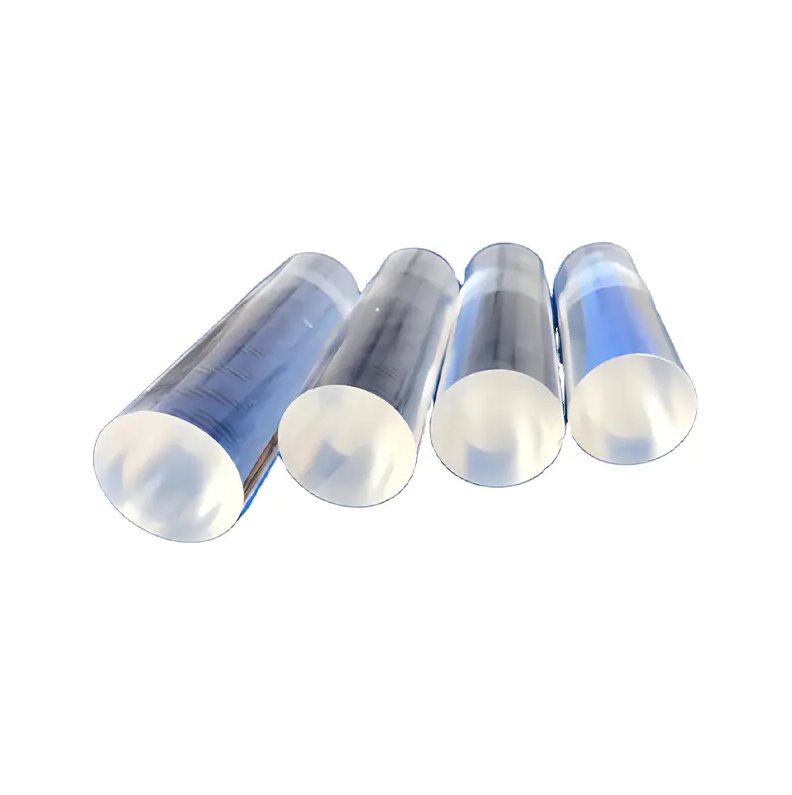

What are the main industrial applications of fused silica rods?

Fused silica rods, due to their excellent high-temperature resistance, superior optical transmittance, and chemical stability, have become an indispensable material in many high-end industrial fields. They can withstand temperatures exceeding 1700℃ and resist corrosive environments such as strong acids and alkalis, making them crucial in modern industrial production.

Content

Semiconductor and Electronics Industry

In semiconductor manufacturing, fused silica rods are widely used in high-temperature furnace tubes, wafer support rods, and other critical high-temperature components. Their low coefficient of thermal expansion (approximately 0.5 × 10⁻⁶/℃) ensures dimensional stability during high-temperature sintering and annealing, preventing wafer deformation. For example, in CVD (chemical vapor deposition) furnaces used in silicon wafer production, fused silica rods can operate continuously for thousands of hours at 1300℃ without cracking.

Optics and Laser Applications

Fused silica rods also have important applications in the fields of optics and lasers. Its high purity and excellent ultraviolet transmittance (UV transmittance can reach over 90%) make it an ideal material for laser optical components and ultraviolet light sources. For example, in 193nm ultraviolet laser etching equipment, fused silica rods are used for beam conduction and protective shielding; their stability directly affects processing accuracy and lifespan.

Chemical Industry and High-Temperature Furnace Manufacturing

In the chemical industry, fused silica rods are commonly used in high-temperature reactors, pipe liners, and corrosive media transport systems. Thanks to their extremely high chemical stability, fused silica rods can be used for extended periods in environments such as concentrated sulfuric acid and hydrofluoric acid, preventing damage to metal materials due to corrosion. Furthermore, in high-temperature furnace equipment such as glass melting furnaces and quartz crucibles, fused silica rods can withstand continuous heat loads exceeding 1600℃, ensuring production safety and stability.

Photovoltaic and New Energy Fields

With the development of the photovoltaic industry, fused silica rods play a crucial role in solar cell manufacturing. They are used in silicon wafer pulling, crystal support, and high-temperature annealing processes, ensuring crystal structure integrity and photoelectric conversion efficiency. For example, in the pulling of monocrystalline silicon rods, fused silica rods can be used for extended periods at around 1500℃ without deformation, ensuring uniform rod diameter and improving the performance of the final photovoltaic modules.

Precision Instruments and Scientific Research Applications

In scientific research laboratories and precision instruments, fused silica rods are widely used in optical instruments, analytical equipment, and experimental reaction devices due to their high purity and stability. For example, in ultraviolet spectrometers and vacuum ultraviolet experiments, fused silica rods ensure high light transmittance of the optical path while withstanding rapid temperature changes, meeting the requirements of high-precision scientific experiments.

Fused silica rods, with their high-temperature resistance, excellent optical properties, and chemical stability, play an irreplaceable role in industrial fields such as semiconductors, optics, chemicals, photovoltaics, and scientific research. With the development of high-end manufacturing, the demand for high-performance fused silica rods continues to grow, providing a reliable material guarantee for industrial production.

- Tel:

+86-0515-86223369

+86-15754187666 - WeChat:

+86-13485219766 - WhatsApp:

+86-13485219766 - E-mail:

[email protected]

[email protected] - Add:

NO.33,yuejinRoad,Science And Technology Pioneer Park,hengji Town,jiangsu county,yancheng city,jiangsu province,china 224763, China

Copyright © Yancheng Mingyang Quartz Products Co., Ltd. All Rights Reserved.

Wholesale Quartz Products Manufacturer Quartz Glass Factory

+86-0515-86223369

+86-0515-86223369  en

en English

English 日本語

日本語 Español

Español