If you need any help, please feel free to contact us

Transparent Glass Tube

InquiryTransparent glass tubes are mainly composed of silicon dioxide (SiO₂) and boron oxide (B₂O₃) (accounting for 78-80% and 12.5-13.5% respectively), supplemented by aluminum oxide (Al₂O₃) and alkali metal oxides (such as Na₂O, K₂O), and a uniform and stable glass structure is formed through a high-temperature melting process. Its core features include:

High light transmittance: Visible light transmittance is as high as 92%, suitable for microscopic observation, spectral analysis, and other scenes requiring optical transparency 27.

Temperature resistance: The thermal expansion coefficient is as low as (3.3±0.1)×10⁻⁶/K, and can withstand an extreme temperature difference of -50℃~500℃ (3 times that of ordinary glass), and there is no risk of deformation or crystallization at high temperatures 15.

Chemical stability: Except for hydrofluoric acid and hot phosphoric acid, it can resist strong acid and alkali corrosion, and maintain permeability after long-term immersion to avoid contamination of experimental samples or industrial materials25.

Mechanical strength: It has high hardness and strong pressure resistance, and can be processed into capillaries with ultra-fine inner diameters (such as 0.6mm) for single cell capture, microreactors, and other precision scenarios24.

|

No. |

Item |

Details |

|

1 |

Product Name |

3.3 Borosilicate Glass |

|

2 |

Main Chemical Components |

SiO₂, Al₂O₃, B₂O₃, Fe₂O₃ |

|

3 |

Coefficient of Expansion |

3.3 |

|

4 |

Operating Temperature |

430°C |

|

5 |

Strain Temperature |

520°C |

|

6 |

Annealing Temperature |

560°C |

|

7 |

Softening Temperature |

815°C |

|

8 |

Density |

2.23g/cm³ |

|

9 |

Refractive Index |

1.472 |

|

10 |

Light Transmittance |

92% |

|

11 |

Acid-Alkali Resistance |

Corrosion - resistant |

|

Technical Parameters |

Details |

|

Density (25°C) |

2.2g/cm² |

|

Coefficient of Expansion (ISO 7991) |

3.25BF10 - 6K⁻¹ |

|

Light Transmittance |

91% |

|

Softening Point |

820°C |

|

Short-term Use < 10h |

550°C |

|

Long-term Use ≥ 10h |

450°C |

|

Refractive Index (587.6nm) |

1.47140 |

|

Knoop Hardness |

480 |

From quotation to delivery, we provide one-stop customer service, responding quickly to customer needs, solving problems efficiently, and completing shipments. Additionally, we offer process optimization and technical support services, including professional workflow improvement, sample preparation and testing, mass production supply, and technical assistance. We meet customers' demands for quartz and specialty glass products.

-

Materials Design

Materials Design

And DevelopmentWe can design and develop quartz and specialty glass according to customer needs and application requirements.

-

Manufacturing Process

Manufacturing Process

OptimizationThe manufacturing process of quartz and specialty glass can be optimized for customers.

-

Sample Preparation

Sample Preparation

And TestingWe provide sample preparation and testing services for new types of quartz and specialty glass.

-

Mass Production

Mass Production

And SupplyOnce approved, quartz and specialty glass can be mass-produced to ensure stable and reliable supply.

-

Technical Support

Technical Support

And ConsultingMingyang can also provide relevant technical support and consulting services to customers.

Global Smart Manufacturing

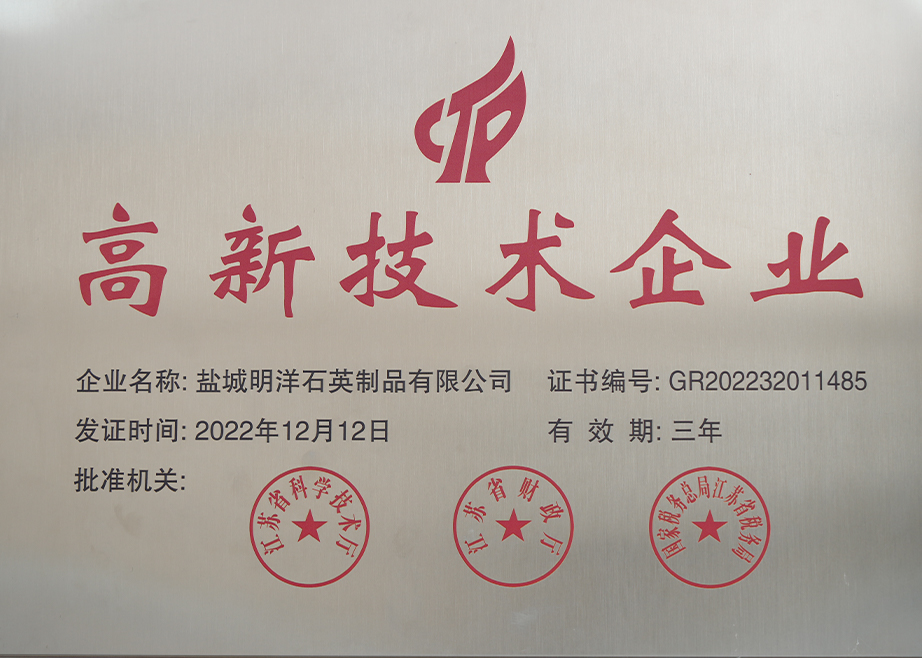

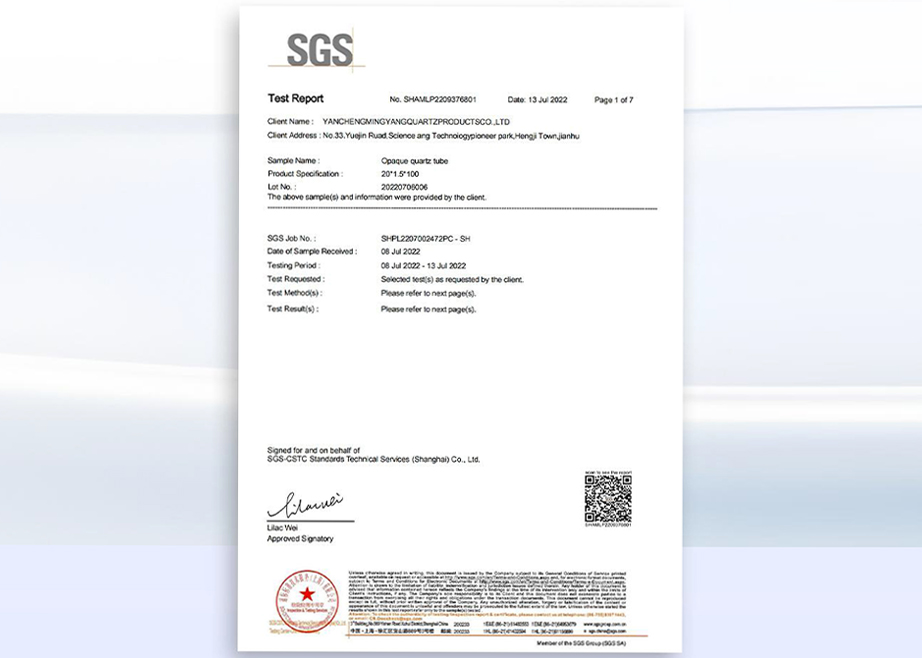

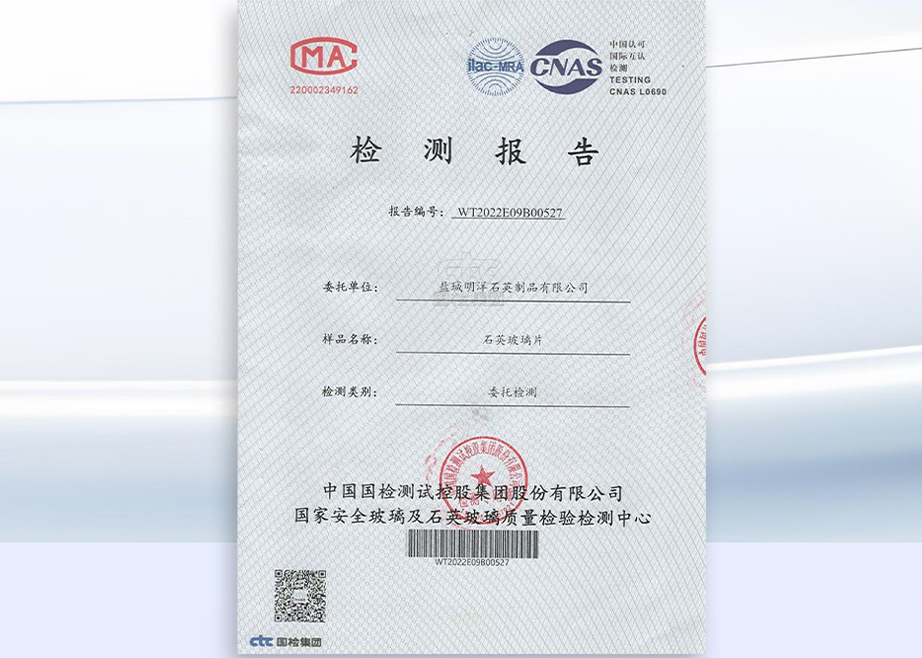

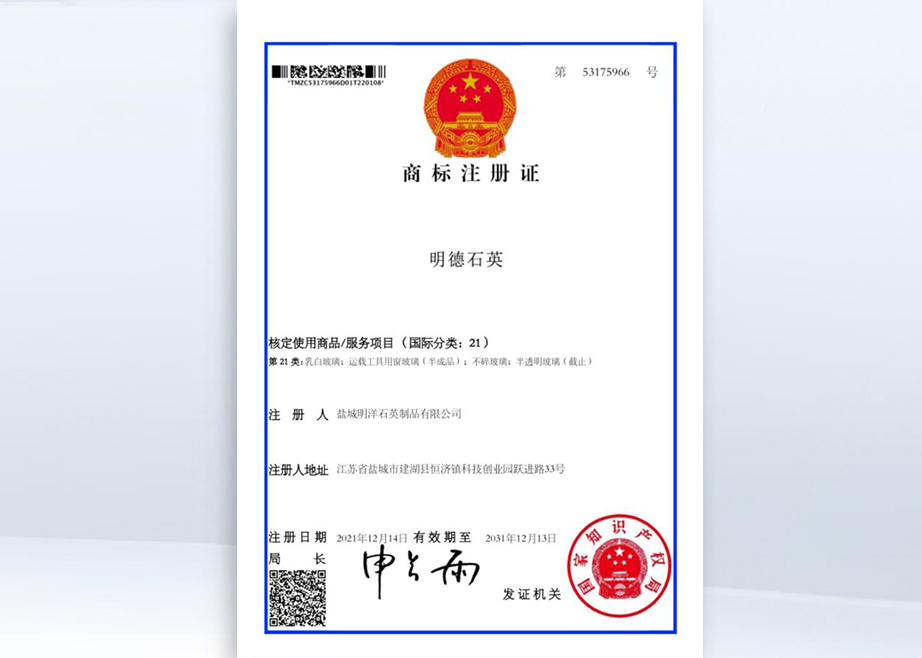

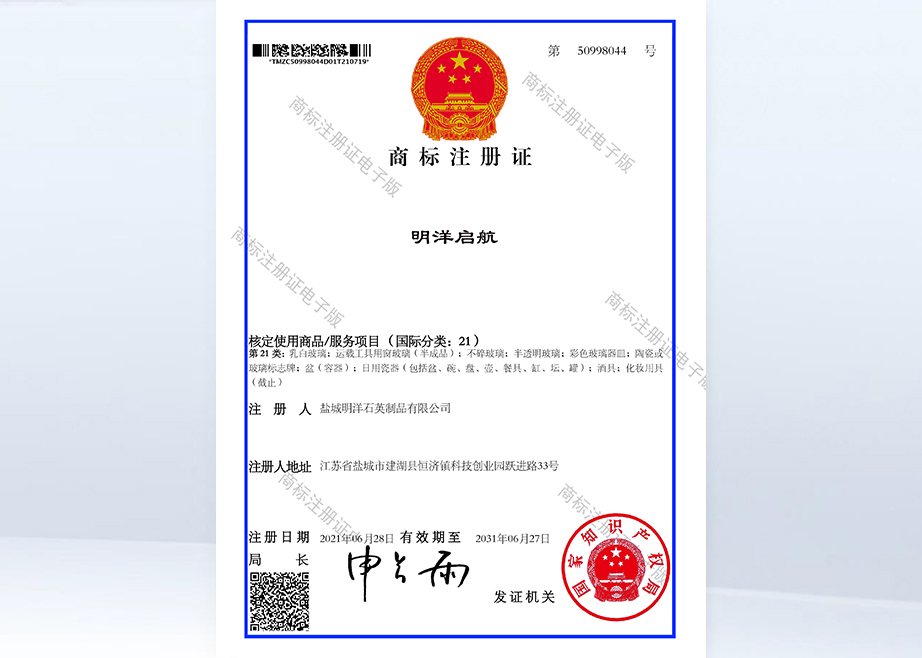

Yancheng Mingyang Quartz Products Co., Ltd. is a company specializing in the production of quartz and special glass products. Yancheng Mingyang Quartz Products Co., Ltd. is the production plant of Jinzhou Mingde Quartz Glass Co., Ltd. in Jiangsu, We are a professional OEM Transparent Glass Tube Manufacturers and Transparent Glass Tube Manufacturers. Since its establishment, the company has developed rapidly, introduced advanced technology and production equipment at home and abroad, and continuously improved and improved product quality. Relying on its own advantages, we have developed a variety of products suitable for the market and meet the needs of different customers, and solved many urgent production problems for our customers.

The company's products include quartz glass tubes, double-hole quartz glass tubes, quartz glass rods, quartz sheets, sapphire windows, calcium fluoride glass windows, infrared ultraviolet coatings, high-pressure resistant aluminosilicate glass window panels, quartz glass instruments, high borosilicate glass instruments, quartz crucibles, quartz gold-plated tubes, quartz heaters, quartz infrared heating tubes, far-infrared directional radiation heaters ultraviolet germicidal lamps and other special types of quartz glass products.

+86-0515-86223369

+86-0515-86223369  en

en English

English 日本語

日本語 Español

Español