If you need any help, please feel free to contact us

What are the main chemical components of quartz glass rods?

The main chemical component of quartz glass rods is silicon dioxide (SiO₂), whose purity is usually above 99.9%, and high-purity quartz glass can even reach 99.9999% (6N grade).

1. Molecular structure of silicon dioxide (SiO₂)

The fundamental reason why quartz glass rods have excellent physical and chemical properties is the special molecular structure of silicon dioxide. Unlike ordinary glass, the microstructure of quartz glass presents a highly stable network-like feature, which directly determines the thermal, optical and mechanical properties of the material.

At the atomic level, the basic structural unit of silicon dioxide is the silicon-oxygen tetrahedron. In this structure, a silicon atom is located in the center, and four oxygen atoms are evenly distributed at the vertices of the tetrahedron. Each oxygen atom forms a strong covalent bond with the central silicon atom. This bonding method has extremely high bond energy, making the entire structure extremely stable.

It is particularly noteworthy that each oxygen atom usually forms a bridge with two silicon atoms, thus connecting adjacent silicon-oxygen tetrahedrons to form a continuous three-dimensional network structure. This unique connection mode provides quartz glass with excellent mechanical strength and chemical stability.

The most notable structural feature of quartz glass is its amorphous nature. Although the arrangement of silicon-oxygen tetrahedrons in the local range remains orderly, the spatial arrangement of these tetrahedrons is completely disordered from a macroscopic scale. This structural feature makes quartz glass is isotropic in physical properties, that is, its properties do not change with the measurement direction.

Compared with crystalline quartz, the amorphous structure causes quartz glass to have no clear melting point, but gradually softens during heating, which is of great significance in practical applications.

Comparing quartz glass with crystalline quartz can more clearly understand its structural characteristics. The silicon-oxygen tetrahedrons in crystalline quartz are arranged according to strict hexagonal crystal system rules to form a long-range ordered crystal structure. This orderly arrangement makes crystalline quartz exhibit anisotropy, such as the famous birefringence phenomenon. However, quartz glass lacks this long-range order and does not produce birefringence, which gives it a unique advantage in optical applications.

The special structure of silica directly determines the key properties of quartz glass. First, the continuous three-dimensional network structure makes the material extremely transparent, and it can maintain excellent transmittance from ultraviolet to infrared bands. Secondly, the network composed of strong covalent bonds can effectively resist the dimensional changes caused by temperature changes, giving the material an extremely low thermal expansion coefficient. Furthermore, the stable silicon-oxygen bonds make quartz glass inert to most chemicals and will only be corroded by hydrofluoric acid and strong alkalis.

In practical applications, even trace amounts of impurity elements can have a significant effect on the network structure of silica. For example, when aluminum ions replace silicon ions and enter the network, structural defects will be caused, resulting in a decrease in the ultraviolet transmittance of the material. Similarly, the introduction of alkali metal ions will interrupt the silicon-oxygen bond network and significantly reduce the material's high temperature resistance. Therefore, in high-performance applications, the purity of the raw materials must be strictly controlled to ensure the integrity of the silica network structure.

2. The difference between quartz glass rod and other glass materials

From the basic composition of the material, quartz glass rod is almost entirely composed of pure silicon dioxide. This extremely high purity makes it form a continuous and uniform three-dimensional network in the microstructure. In contrast, ordinary glass such as soda-lime glass is much more complex in composition, and contains a large amount of modified oxides in addition to silicon dioxide.

Although these added components improve the processing performance of ordinary glass, they also fundamentally change the essential properties of the material. Borosilicate glass, as another common type, has a composition between the two, and a relatively balanced performance is obtained by adding boron oxide.

In terms of thermal properties, quartz glass rods show excellent stability. Due to its pure silicon dioxide structure and strong silicon-oxygen bonding force, quartz glass can withstand extreme high temperatures without softening and deformation. This property makes it an ideal choice for high-temperature experiments and industrial applications.

Ordinary glass begins to soften at relatively low temperatures, which severely limits its use in high-temperature environments. Although borosilicate glass has improved heat resistance to a certain extent, it still cannot reach the level of quartz glass.

Quartz glass rods have extremely excellent light transmission characteristics due to their highly pure composition and uniform structure. It can not only transmit visible light, but also allow ultraviolet and infrared rays to pass smoothly. This wide-band light transmission ability is difficult for other glass materials to achieve.

Ordinary glass contains various metal ions and impurities, which has a very obvious blocking effect on ultraviolet rays, which makes it completely unable to replace quartz glass in applications that require ultraviolet transmission. Although the optical properties of borosilicate glass are better than ordinary glass, its light transmittance in the ultraviolet region is still lower than that of quartz glass.

In terms of chemical stability, quartz glass rods also perform outstandingly. It has strong resistance to most acid substances and will only be corroded by a few highly corrosive substances such as hydrofluoric acid. This excellent corrosion resistance makes it widely used in the chemical industry. The chemical stability of ordinary glass is relatively poor, especially in alkaline environments. Although the chemical resistance of borosilicate glass has been improved, it is still not comparable to quartz glass.

From a microscopic perspective, another important feature of quartz glass is its extremely low thermal expansion coefficient. This means that the size of quartz glass hardly changes significantly when the temperature changes. This property makes it irreplaceable in precision optical instruments and environments with drastic temperature changes. Ordinary glass has much greater thermal expansion, which can cause stress and even cracking when the temperature fluctuates. Borosilicate glass reduces thermal expansion through a special composition formula, but it still does not perform as well as quartz glass.

In actual application scenarios, these performance differences directly determine the applicable fields of different glass materials. Quartz glass rods are widely used in high-end fields such as semiconductor manufacturing, precision optics, and high-temperature experiments due to their excellent comprehensive performance.

Ordinary glass is mainly used in daily necessities and construction fields. Its advantages are low cost and easy processing. Borosilicate glass has found its own market position and is used in laboratory utensils and some special lamps.

| Performance category | Quartz glass rod | Ordinary glass (soda-lime glass) | Borosilicate glass |

| Material composition | Almost entirely composed of pure silicon dioxide (SiO₂), with uniform structure | Contains a large amount of sodium, calcium and other oxides, with complex composition | Contains silicon dioxide and boron oxide (B₂O₃), with a composition between the two |

| Thermal properties | Excellent thermal stability, can withstand extremely high temperatures without softening | Poor thermal stability, easy to soften at low temperatures | Has good thermal stability, but not as good as quartz glass |

| Light transmittance | High light transmittance, can pass visible light, ultraviolet light and infrared light | Low light transmittance, obvious UV blocking | Has better light transmittance than ordinary glass, but still lower UV transmittance than quartz glass |

| Chemical stability | Extremely chemically inert, only sensitive to strong acids such as hydrofluoric acid | Poor chemical stability, easy to be corroded by alkaline substances | Has good chemical stability, but not as good as quartz glass |

| Coefficient of thermal expansion | Extremely low (about 1/10 of ordinary glass), good dimensional stability | High, easy to produce stress or cracking due to temperature changes | The thermal expansion coefficient is reduced by adding boron oxide, but still higher than quartz glass |

| Main application areas | Semiconductor manufacturing, precision optics, high temperature experiments | Daily necessities, construction, general appliances | Laboratory utensils, special lamps, some optical devices |

| Cost and processability | High cost, difficult processing | Low cost, easy to process | Moderate cost, good processing performance |

3. Quartz glass rod production process

The production of quartz glass rods is a complex process that integrates material science, high temperature technology and precision processing. The core lies in how to convert silica raw materials into rod-shaped products with specific performance and size requirements. The entire production process can be divided into four main stages: raw material processing, melt molding, drawing molding and post-processing. Each stage requires strict control to ensure the quality of the final product.

(1). Raw material preparation and pretreatment

The first link in quartz glass production is the selection and purification of raw materials. According to the product grade requirements, natural quartz sand or synthetic silica can be selected as raw materials. For quartz rods with high purity requirements, synthetic silica prepared by chemical vapor deposition is usually used, and its purity can reach more than 99.9999%.

The raw materials need to undergo multiple purification processes before entering the melting process: first, pickling is used to remove metal impurities, then high-temperature chlorination treatment is carried out for further purification, and finally precision screening is used to ensure uniform particle size. The processing quality at this stage directly affects the optical properties and thermal stability of the final product.

(2). High-temperature melting process

Melting is the core link of quartz glass production. Currently, three melting technologies are mainly used in the industry:

Electric melting is the most traditional production process. In a vacuum or inert gas protection environment, the quartz sand is melted by a high-temperature arc generated by a graphite electrode. This method has relatively low equipment investment and is suitable for the production of large-sized quartz rods, but a small amount of carbon impurities may remain in the product.

The gas refining method uses a hydrogen-oxygen flame as a heat source, and the temperature can reach above 2000°C. High-purity quartz sand is melted in the hydrogen-oxygen flame, and extremely high-purity quartz glass can be obtained by precisely controlling the flame temperature and melting time. This method is particularly suitable for the production of optical-grade quartz rods, but the energy consumption is high and the production efficiency is relatively low.

Plasma melting is a high-end technology developed in recent years. It uses a plasma torch to generate ultra-high temperature (up to 3000°C) to melt the raw materials instantly. The advantage of this method is that it can produce ultra-high purity quartz glass, which is almost free of hydroxyl and other impurities, and is particularly suitable for semiconductor and optical fiber applications, but the equipment is complex and costly.

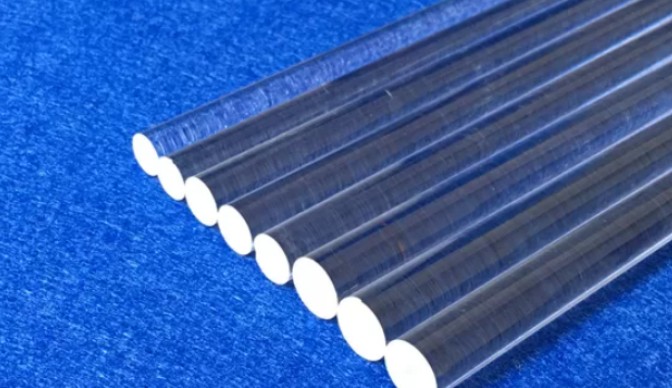

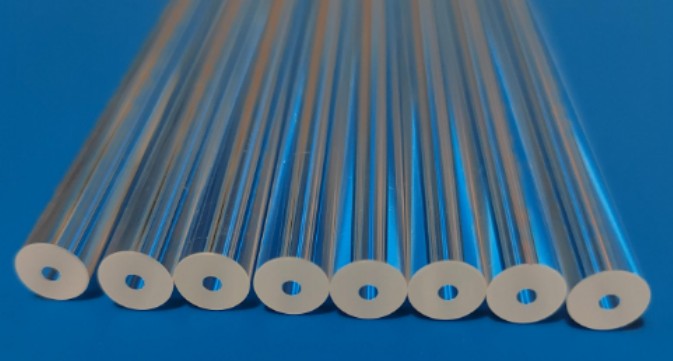

(3). Molding and drawing process

The molten quartz glass needs to be precisely molded to obtain rods that meet the requirements. There are two main molding methods:

The mold molding method injects molten quartz into a special mold and obtains the desired shape by precisely controlling the cooling rate. This method is suitable for producing large-diameter quartz rods, but there may be stress concentration inside the product.

The continuous drawing method is the most commonly used production process. The molten quartz flows out of a special leak plate and is drawn at a constant speed through a precisely controlled traction system. By adjusting the drawing speed and temperature, different specifications of products with diameters ranging from a few millimeters to hundreds of millimeters can be obtained. The temperature gradient and cooling rate need to be precisely controlled during the drawing process to ensure the dimensional accuracy and internal quality of the rod.

(4). Precision annealing treatment

The newly formed quartz rod must undergo a strict annealing process to eliminate internal stress. The annealing process is usually carried out in a special annealing furnace, with the temperature controlled between 1100-1200℃, and the insulation time depends on the size of the rod. The key is to strictly control the cooling rate. Usually, the cooling method is segmented. It may take several days from the high temperature zone to the low temperature zone. Perfect annealing can significantly improve the thermal stability and mechanical strength of the quartz rod.

(5). Post-processing and finishing

The annealed quartz rod also needs to go through multiple precision machining processes:

Machining includes cylindrical grinding, end face grinding, etc. to ensure dimensional accuracy and surface finish. For quartz rods with special requirements, complex processing such as drilling and grooving may be required.

Surface treatment is a key step to improve performance, including processes such as fire polishing and chemical etching. Fire polishing uses a high-temperature flame to micro-melt the surface to obtain an optically smooth surface; chemical etching is used to remove the processing damage layer and improve strength.

Special treatments may include: UV irradiation to improve optical properties, high-temperature heat treatment to reduce the hydroxyl content, or surface coating to enhance specific functions according to application requirements.

6. Quality inspection and control

The finished quartz rod needs to go through a series of strict quality inspection processes before leaving the factory. These inspection items cover multiple key performance indicators of the material, such as optics, physics, thermal and chemistry. In the optical performance test, technicians will use a precision spectrophotometer to measure the transmittance characteristics of the quartz rod at different wavelengths, paying special attention to its transmittance performance in the ultraviolet and infrared bands.

At the same time, laser interferometers and other equipment will be used to detect the uniformity of the refractive index to ensure that the optical performance of the entire quartz rod meets the design requirements. These optical test data are crucial to determine whether the quartz rod is suitable for precision optical systems.

Geometric dimension accuracy detection is the basic link of quality control. The inspectors will use high-precision calipers, micrometers and other measuring tools to measure the basic dimensions of the quartz rod, such as diameter, length, and roundness. For high-demand applications, a three-coordinate measuring machine may also be used for more precise dimensional detection to ensure that the geometric tolerance of the quartz rod is controlled within the allowable range. This test is directly related to the matching accuracy of the quartz rod in the subsequent assembly and use process.

Internal defect inspection is mainly completed by professional testing equipment. Common methods include optical microscope observation, X-ray flaw detection and ultrasonic testing. These detection methods can accurately identify the defects such as bubbles, impurities, cracks, etc. that may exist inside the quartz rod, and determine the product grade according to the size, quantity and distribution of the defects. Especially for optical and semiconductor grade quartz rods, the control standards for internal defects are more stringent, and usually require no visible defects at all.

Thermal performance testing mainly includes two important items: thermal expansion coefficient test and thermal shock resistance test. The thermal expansion coefficient test uses a thermomechanical analyzer to measure the dimensional changes of the quartz rod at different temperatures. The thermal shock resistance test is to quickly switch the quartz rod between high and low temperature environments to observe its crack resistance. These thermal performance data are of great reference value for evaluating the reliability of quartz rods in temperature change environments.

Chemical stability testing mainly evaluates the tolerance of quartz rods in various chemical environments. Common testing methods include immersing quartz rod samples in acid and alkali solutions of different concentrations, observing their surface changes, and measuring the weight changes and surface roughness changes before and after immersion.

Among them, the test of resistance to hydrofluoric acid is particularly important, because quartz glass is particularly susceptible to corrosion in a hydrofluoric acid environment. Through these comprehensive quality tests, it can be ensured that each quartz rod shipped from the factory meets strict quality standards and meets the special requirements of different application scenarios.

7. Application fields of quartz glass rods

In the field of optical engineering, quartz glass rods play a vital role. Due to its excellent UV-visible-infrared full-band light transmittance, it is an ideal material for manufacturing high-precision optical components. In laser technology applications, quartz rods are often used as resonant cavity media and optical windows of lasers, especially in high-power CO2 lasers, where quartz rods can withstand extremely strong laser energy without damage.

In optical fiber communication systems, ultra-high purity quartz glass rods are precisely drawn to form optical fiber preforms, which are the core raw materials for manufacturing communication optical fibers. In the manufacture of optical instruments, quartz rods are processed into various lenses, prisms and optical windows, which are widely used in high-precision optical equipment such as spectrometers and microscopes.

The semiconductor industry is particularly dependent on quartz glass rods. During the wafer manufacturing process, quartz rods are made into various shapes of wafer carriers, diffusion tubes and reaction chamber components. These components need to withstand the high temperature environment in the semiconductor manufacturing process, and must ensure that no contaminating impurities are introduced.

In advanced extreme ultraviolet (EUV) lithography technology, optical components made of quartz glass have become the key to achieving nano-level lithography accuracy due to their extremely low thermal expansion coefficient and excellent optical uniformity. In addition, quartz glass rods are also widely used in observation windows, gas delivery pipelines and other parts of semiconductor equipment due to their chemical inertness.

The chemical industry fully utilizes the corrosion resistance of quartz glass rods. In chemical reactors under strong acid environments, quartz observation windows can withstand various strong acid erosions except hydrofluoric acid for a long time. Corrosive medium delivery pipelines, stirring rods and other components in chemical production are also often made of quartz glass.

It is particularly worth mentioning that in high-temperature and high-pressure chemical reaction experiments, quartz reaction vessels can withstand harsh temperatures and chemical environments at the same time, providing reliable experimental conditions for researchers. Quartz glass performs far better than ordinary glass and most metal materials in these applications.

In recent years, quartz glass materials have been increasingly used in the medical and health field. In terms of medical equipment, quartz rods are used to manufacture optical transmission components of endoscopes, light-guiding elements of laser surgical instruments, etc. Its excellent biocompatibility ensures that these instruments can be safely used for human treatment.

In ultraviolet disinfection equipment, high-transmittance quartz glass rods are used as lamp materials to maximize the sterilization efficiency. In addition, in some precision medical testing instruments, quartz optical elements ensure the accuracy of the test results.

The demand for quartz glass rods in the field of scientific research and experiment is also strong. In high-energy physics experiments, quartz rods are used as important components of Cherenkov radiation detectors. In materials science research, quartz crucibles and reaction vessels provide an ideal environment for high-temperature material synthesis.

In the field of space science, the radiation resistance of quartz glass makes it the preferred material for spacecraft optical systems. These high-end scientific research applications often have extreme requirements for material properties, and quartz glass rods can always perform the task excellently.

| Application areas | Main Application | Key performance advantages | Typical application scenarios |

| Optical engineering | Manufacturing high-precision optical components | High transmittance in the entire band (UV-visible-infrared) | Laser resonator, optical window, lens, prism, spectrometer, microscope |

| Fiber optic communication | Optical fiber preform manufacturing | Ultra-high purity, high uniformity | Fiber optic communication system, long-distance signal transmission |

| Semiconductor industry | Wafer manufacturing, diffusion tubes, reaction chamber components | High temperature stability, chemical inertness, low thermal expansion coefficient | Extreme ultraviolet (EUV) lithography, wafer carrier, observation window, gas delivery pipeline |

| Chemical industry | Chemical reactors, delivery pipes, stirring rods | Resistant to strong acid corrosion (except hydrofluoric acid) | Reactor in strong acid environment, corrosive medium delivery system |

| Medical and health care | Endoscope optical transmission components, laser surgical instruments | Biocompatibility, high transmittance | Ultraviolet disinfection equipment, medical testing equipment, laser surgery equipment |

| Scientific research and experiment | High-energy physics detectors, material synthesis containers | High temperature resistance, radiation resistance, high stability | Cherenkov radiation detector, high-temperature material synthesis, spacecraft optical system |

+86-0515-86223369

+86-0515-86223369  en

en English

English 日本語

日本語 Español

Español