If you need any help, please feel free to contact us

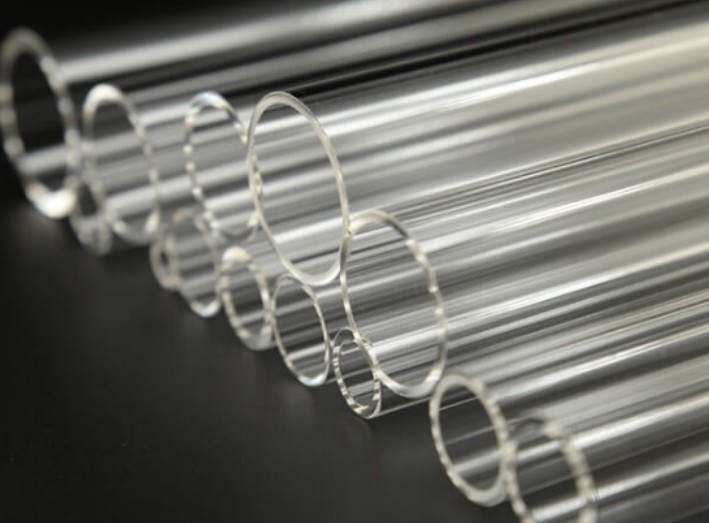

What is a quartz glass tube?

Quartz glass tube is a special glass material made of ultra-high purity silica raw material, which is melted at high temperature and then precisely processed. With its excellent comprehensive performance, it plays an irreplaceable role in high-tech fields such as semiconductors, optoelectronics, new energy and scientific research instruments.

The most prominent feature of this material is its excellent high temperature resistance, which can withstand extreme temperature environments without deformation or cracking, and its excellent thermal shock resistance, which can adapt to rapid temperature changes. In terms of optics, quartz glass tubes have extremely high light transmittance and are suitable for a wide range of spectra from ultraviolet to infrared. In addition, it also exhibits extremely strong chemical stability, can resist most strong acids and high temperature corrosion, and ensure long-term stable use in harsh environments.

Quartz glass tubes also have excellent electrical insulation properties and mechanical strength, making them ideal for precision electronic and optical devices. Modern manufacturing technology can produce large-sized, high-purity quartz tubes, and can adjust their performance through special processes to meet the needs of different application scenarios. Whether it is semiconductor manufacturing, fiber optic communications, or high-end scientific research equipment, quartz glass tubes play a key role and promote the development of cutting-edge technology.

1. Material properties

Chemical properties

The excellent chemical stability of quartz glass tubes comes from their special material composition and structure. This high-purity silica material exhibits nearly perfect chemical inertness and hardly reacts with other substances at room temperature. It has strong resistance to most inorganic acids and organic solvents, including strong acids such as concentrated sulfuric acid, nitric acid, and hydrochloric acid, as well as organic compounds such as alcohols and ketones. Even under high temperature conditions, quartz glass tubes can maintain this stable chemical property, which makes it an ideal container material for handling corrosive substances.

Quartz glass tubes have weak resistance to hydrofluoric acid and hot phosphoric acid because these substances can react specifically with silica. Similarly, quartz glass tubes are also susceptible to corrosion in high-temperature and strong alkaline environments. In practical applications, special attention should be paid to avoid contact with these specific chemical environments. It is this unique chemical stability that makes quartz glass tubes widely used in fields such as semiconductor manufacturing and chemical production that require extremely high material purity.

Thermal properties

Quartz glass tubes can continuously withstand ultra-high temperature environments that ordinary metal materials cannot cope with. This excellent heat resistance comes from its special atomic structure. Even under extremely high temperature conditions, quartz glass tubes can maintain structural integrity without softening and deformation. Even more amazing is that it hardly changes size when experiencing drastic temperature changes, which is extremely rare in materials science.

This unique thermal stability makes quartz glass tubes an ideal choice for extreme temperature environments. It can repeatedly undergo rapid cooling from ultra-high temperature to room temperature without cracking or breaking, which is important in industrial processes that require frequent thermal cycles. At the same time, the relatively low thermal conductivity of quartz glass tubes makes it an excellent thermal insulation material that can effectively block the radiation and conduction of high-temperature heat sources.

Optical properties

Quartz glass tubes show unparalleled advantages in optical properties. It has an extremely wide spectral transmittance range and can efficiently transmit electromagnetic waves from deep ultraviolet to near infrared regions. This excellent optical property makes it a core component of precision optical systems. According to different application requirements, the optical properties of quartz glass tubes can also be adjusted in a targeted manner.

Through special processing, quartz glass tubes with specific optical properties can be manufactured. For example, milky quartz tubes achieve uniform scattering of light through internal microbubble structures, which are suitable for occasions requiring soft lighting; adding specific elements can produce colored quartz tubes with selective light transmission characteristics for special optical filtering devices. These adjustable optical properties greatly expand the application range of quartz glass tubes.

Mechanical and electrical properties

Although quartz glass tubes have high hardness and strength, their brittle characteristics require special attention. This material is prone to cracking when subjected to impact or local stress, so special care is required during handling, installation and use. Through fine surface treatment technology, quartz glass tubes can obtain extremely high surface finish to meet the most stringent optical application requirements.

In terms of electrical properties, quartz glass tubes exhibit excellent insulation properties. Even at high temperatures, it can still maintain good dielectric properties without significant changes in conductivity. This stable insulation property makes it an ideal insulating material for high-voltage electrical equipment and electronic components. At the same time, quartz glass tubes also have excellent arc resistance and can be used safely in strong electric field environments.

Surface and processing characteristics

The surface and processing characteristics of quartz glass tubes enable them to meet the needs of various precision applications. Its natural surface has a high degree of finish, and after precision polishing, it can achieve near-perfect flatness, meeting the stringent requirements of laser-grade optical components. The surface of quartz glass tubes can be plated with a variety of special coatings, such as anti-reflection coatings that can significantly increase transmittance, and conductive coatings that can give it conductive properties.

In terms of processing technology, hot processing of quartz glass tubes requires extremely high temperatures, and usually special hydrogen-oxygen flame equipment is used to achieve welding or hot forming; while cold processing requires diamond tools for cutting and drilling, and flame polishing of the edges after processing to prevent microcracks from expanding and affecting material strength.

2. Manufacturing process

The manufacturing process of quartz glass tube is a highly sophisticated process that requires strict quality control to ensure that the final product has excellent performance. The current mainstream manufacturing methods include melt drawing and processing molding, and each process is designed for different product requirements.

Melt drawing production process

As the core technology of continuous production, the melt drawing method has a very precise process flow. At the beginning of production, selected high-purity quartz sand raw materials are fed into a special high-temperature furnace. This furnace uses a special heating method to produce an ultra-high temperature environment sufficient to completely melt the quartz. During the melting process, the raw materials undergo a strict purification stage, and trace impurities and bubbles are removed through high-temperature volatilization and chemical reactions.

The molten quartz glass liquid enters the molding area, where a precise mold system shapes the liquid glass into a tubular structure. The design and manufacture of the mold requires extremely high precision, and its dimensional tolerance is controlled within a very small range.

During the drawing process, the precisely controlled temperature gradient ensures that the glass liquid maintains the best viscosity and fluidity during molding. At the same time, the computer-controlled traction system stretches the glass tube at a constant speed, and this speed needs to be perfectly matched with the cooling rate of the glass liquid to ensure the uniformity of the tube wall thickness.

After forming, the quartz glass tube enters the annealing process, which is a key step to ensure product quality. The annealing furnace adopts a zoned temperature control design to allow the glass tube to cool slowly according to the preset temperature curve. This process can effectively eliminate the residual stress inside the glass and avoid cracking or deformation of the product during subsequent processing or use. The annealed product also needs to undergo strict quality inspection, including dimensional measurement, stress analysis and optical performance testing.

Processing molding production process

The processing molding method is mainly used in the production of special-shaped quartz glass products, and its process characteristics focus more on flexibility and precision. The process uses high-quality prefabricated quartz glass materials as raw materials, which have been strictly screened and pretreated.

During the processing, the operator uses specially designed thermal processing equipment to locally heat the quartz glass. The heating temperature needs to be precisely controlled to achieve sufficient softening for molding and avoid excessive heating that will damage the material properties. Experienced technicians will judge the best time to process by observing the viscous flow state of the glass.

For products with complex shapes, such as multi-elbow pipes or special-shaped connectors, special molds are usually required to complete the molding. The mold material must be able to withstand the processing temperature of quartz glass while ensuring the smoothness of the molding surface. In some high-precision occasions, computer-aided CNC machining equipment is also used to achieve more precise molding control.

The products after processing and molding also need to undergo fine annealing. Unlike the fusion drawing method, the annealing process of these special-shaped products often requires customized temperature curves to cope with the stress relief needs of different thickness parts. Finally, each product must undergo strict appearance inspection, dimensional measurement and performance testing to ensure that it meets the requirements of use.

The quality control system of both processes includes multiple links such as raw material inspection, process monitoring and finished product inspection. The modern production line is also equipped with an online monitoring system to monitor key process parameters in real time to ensure the stability of the production process and the consistency of product performance.

Through these precise manufacturing processes, quartz glass tubes can meet the stringent requirements for material performance in high-end fields such as semiconductors and optics.

3. Main classification

Transparent quartz tube

As the most basic type, the excellent performance of transparent quartz glass tube comes from the strictly controlled manufacturing process. This kind of tube uses ultra-high purity quartz sand as raw material, and is removed by a special smelting process to form a highly homogeneous amorphous structure. Its microstructure is dense and uniform, and there are almost no light scattering centers, so it has excellent optical transmittance. It can maintain stable transmittance in a wide spectrum from deep ultraviolet to near infrared, which makes it an ideal material for optical systems.

In the semiconductor industry, transparent quartz tubes are widely used as key components such as diffusion furnace tubes and epitaxial reaction tubes due to their chemical inertness and thermal stability. In the field of lighting, it is used to manufacture the light-emitting cavity of special light sources such as high-pressure gas discharge lamps and ultraviolet germicidal lamps. It is often used as a key optical component such as optical windows and sample cells in scientific research instruments. It is also commonly used in medical equipment as an optical transmission component of instruments such as endoscopes.

Oval quartz tube

The special appearance of the opal quartz tube comes from the submicron bubble network evenly distributed inside it. These bubbles are formed by precisely controlling the process parameters during the melting process, and their size and distribution density directly affect the optical properties of the tube. The bubble structure not only produces a soft light scattering effect, but also significantly reduces the thermal conductivity of the material, making it have good thermal insulation properties.

In the field of infrared heating, opalescent quartz tubes can evenly disperse thermal radiation and avoid local overheating. It is often used as a heating element protection tube in food processing equipment, which can ensure heating efficiency and prevent food from burning. In special lighting devices, it is used to create a glare-free uniform surface light source. Some analytical instruments also use opalescent quartz tubes as sample chambers to obtain a uniform detection light path.

Colored quartz tubes

The manufacturing process requirements of colored quartz tubes are extremely high, and stable coloring effects need to be achieved while maintaining the basic properties of quartz glass. The coloring process usually uses a high-temperature melting method to evenly incorporate specific metal oxides into the quartz matrix. Different colorants will produce characteristic absorption spectra, such as cobalt elements produce blue, manganese elements produce purple, etc.

These colored tubes are not only decorative, but more importantly, they have selective filtering properties. In stage lighting systems, colored quartz tubes can directly produce specific color light. In optical experimental devices, it can be used as a filter element for specific wavelengths. Some industrial detection equipment also uses its filtering properties for spectral analysis. Specially formulated colored tubes can also shield harmful radiation and are used in protective devices.

Special-shaped quartz tubes

The manufacture of special-shaped quartz tubes fully demonstrates the flexibility of quartz glass processing technology. According to application requirements, it can be made into various complex geometric shapes, including multi-angle bends, T-shaped three-way tubes, reducing connection tubes, etc. These special shapes usually require a combination of multiple processing technologies, such as hot bending, precision welding, and machining.

In semiconductor equipment, special-shaped quartz tubes are used to build complex gas delivery systems. In chemical production, special-shaped quartz tubes can meet demanding process requirements. Scientific research experimental devices often require customized quartz piping systems. Some medical equipment also uses special-shaped quartz tubes as key functional components.

Low-hydroxyl tubes

The manufacture of low-hydroxyl quartz tubes requires special process control. The hydroxyl content in the material can be significantly reduced by optimizing the melting atmosphere, using vacuum degassing technology, and using high-purity raw materials. More advanced technologies also include special processes such as subsequent plasma treatment.

In the field of laser technology, low hydroxyl tubes greatly reduce infrared absorption losses and are the core components of high-power lasers. In precision optical systems, it can reduce optical distortion caused by hydroxyl groups. Some special light source equipment also requires low hydroxyl tubes to ensure spectral purity. In the field of optical fiber communications, it is used as a preform material for low-loss optical fibers.

| Type | Features | Application areas |

| Transparent quartz tube | High purity, high transmittance, low hydroxyl content, no light scattering center, suitable for a wide spectral range | Semiconductor industry (diffusion furnace tubes, epitaxial reaction tubes), lighting (high-pressure gas discharge lamps, ultraviolet sterilization lamps), scientific research instruments (optical windows, sample pools), medical devices (endoscopes) |

| Milky quartz tube | Evenly distributed submicron bubble network inside, produces soft light scattering, reduces thermal conductivity, and has good thermal insulation performance | Infrared heating equipment (protective tubes for heating elements of food processing equipment), lighting devices (glare-free uniform surface light sources), analytical instruments (sample chambers) |

| Colored quartz tube | Colored by adding metal oxides through high-temperature melting method, with selective filtering performance | Stage lighting systems (specific color light sources), optical experimental devices (filter elements), industrial testing equipment (spectral analysis), protective devices (shielding harmful radiation) |

| Special shaped quartz tube | Can be made into complex geometric shapes according to needs, such as elbows, tees, etc. | Semiconductor equipment (gas delivery systems), chemical production (strict process requirements), scientific research experimental devices (customized pipeline systems), medical equipment (key functional components) |

| Low hydroxyl tube | Special processes significantly reduce the hydroxyl content, reduce infrared absorption losses and optical distortion | Laser technology (high-power lasers), precision optical systems (reducing optical distortion), optical fiber communications (low-loss optical fiber preforms) |

4. Core application areas

In the field of optoelectronic technology, quartz glass tubes play an irreplaceable role. As a core component of special light sources, it is widely used in the manufacture of high-intensity gas discharge lamps, including metal halide lamps, high-pressure sodium lamps, etc. These lighting equipment can reach an internal temperature of thousands of degrees Celsius when working, accompanied by strong ultraviolet radiation.

Quartz glass tubes are perfectly qualified with their high temperature resistance and anti-ultraviolet properties. In the application of ultraviolet technology, quartz glass tubes are the preferred material for manufacturing UV sterilization lamps, ultraviolet curing lamps and other equipment. Their excellent ultraviolet transmittance ensures sterilization and curing effects.

The field of optical fiber communications is inseparable from quartz glass tubes. As the base material of the optical fiber preform, the high-purity quartz tube undergoes a complex deposition and drawing process to eventually form an optical fiber that transmits optical signals. In laser technology, specially treated quartz glass tubes are used to manufacture key components such as the laser's resonant cavity and output window. Their excellent optical uniformity and thermal stability ensure the quality and stability of the laser output.

Semiconductor manufacturing is highly dependent on quartz glass tubes. Quartz glass tubes play an important role in many key links in chip production. In the growth process of single crystal silicon, high-purity quartz crucibles and thermal field components ensure a pure environment for crystal growth. In high-temperature processes such as diffusion and oxidation, quartz glass tubes are used as process cavities and gas delivery pipelines to withstand corrosive gases and extreme temperatures.

In wafer processing equipment, quartz glass tubes are made into key components such as wafer carriers and gas distributors of various shapes. The photovoltaic industry also uses a large number of quartz glass tubes, especially in polycrystalline silicon ingots and single crystal silicon growth equipment. The purity of quartz tubes directly affects the conversion efficiency of solar cells. With the continuous advancement of semiconductor process nodes, the purity and flatness requirements of quartz glass tubes are becoming higher and higher.

The chemical industry makes full use of the excellent chemical stability of quartz glass tubes. In the process of treating corrosive media such as strong acids and strong alkalis, quartz glass reactors, heat exchangers and other equipment show excellent corrosion resistance. In the laboratory, quartz glass tubes are made into various precision experimental devices, such as spectral analysis sample cells, high-temperature reaction tubes, etc., and their chemical inertness ensures the accuracy of experimental data.

In the field of analytical testing, quartz cuvettes, optical prisms and other components ensure the accuracy of spectral measurement. Scientific research institutions often use quartz glass tubes to build special experimental devices, such as high-temperature observation windows, vacuum system components, etc., to meet the experimental needs under extreme conditions. The application of quartz glass tubes in these fields has greatly expanded the possibilities of chemical research and experiments.

In the field of industrial heating, quartz glass tubes are widely used as radiation tubes and protective sleeves for infrared heaters. Its high temperature resistance enables heating equipment to work stably and for a long time in harsh environments. In medical sterilization equipment, sterilization containers made of quartz glass tubes can withstand repeated sterilization of high-temperature and high-pressure steam.

Key components such as observation windows and sensor protection covers of aircraft and spacecraft are made of special quartz glass tubes to ensure reliability in extreme environments. The food processing industry uses the safety and non-toxic properties of quartz glass tubes to apply them to heating devices that come into direct contact with food, such as heating tubes for baking equipment.

| Application areas | Specific applications | Product type | Features |

| Optoelectronic technology | High-intensity gas discharge lamps (such as metal halide lamps, high-pressure sodium lamps) | transparent quartz tube | High temperature resistance, UV resistance, high light transmittance |

| Optoelectronic technology | Ultraviolet germicidal lamps, ultraviolet curing lamps | transparent quartz tube | Excellent UV transmittance |

| Fiber optic communication | Optical fiber preforms | high purity quartz tube | Used to manufacture optical fiber for transmitting optical signals |

| Laser technology | Laser resonator, output window | low hydroxyl quartz tube | Good optical uniformity, high thermal stability |

| Semiconductor manufacturing | Single crystal silicon growth, diffusion, oxidation process | transparent quartz tube, low hydroxyl quartz tube | High purity, high temperature resistance, good chemical stability |

| Semiconductor manufacturing | Wafer carrier, gas distributor in wafer processing equipment | special quartz tube | Customization, high temperature resistance, corrosion resistance |

| Photovoltaic industry | Polycrystalline silicon ingot, single crystal silicon growth equipment | transparent quartz tube | Purity affects solar cell efficiency |

| Chemical industry | Strong acid, strong alkali treatment equipment | transparent quartz tube, low hydroxyl quartz tube | Chemical inertness, corrosion resistance |

| Laboratory | Spectral analysis sample pool, high temperature reaction tube | transparent quartz tube, low hydroxyl quartz tube | Good chemical stability, excellent optical properties |

| Analytical testing | Spectroscopic cuvettes, optical prisms | transparent quartz tube | Good optical uniformity |

| Industrial heating | Radiant tubes, infrared heater protective sleeves | milky quartz tube | High temperature resistance, good thermal insulation performance |

| Medical sterilization | High-temperature and high-pressure steam sterilization containers | transparent quartz tube | High temperature resistance, non-toxic |

| Aerospace | Aircraft and spacecraft observation windows, sensor protective covers | special quartz glass tube | High temperature resistance, radiation resistance, high reliability |

| Food processing | Heating devices that come into direct contact with food | transparent quartz tube | Safe and non-toxic, high temperature resistance |

+86-0515-86223369

+86-0515-86223369  en

en English

English 日本語

日本語 Español

Español