Introduction

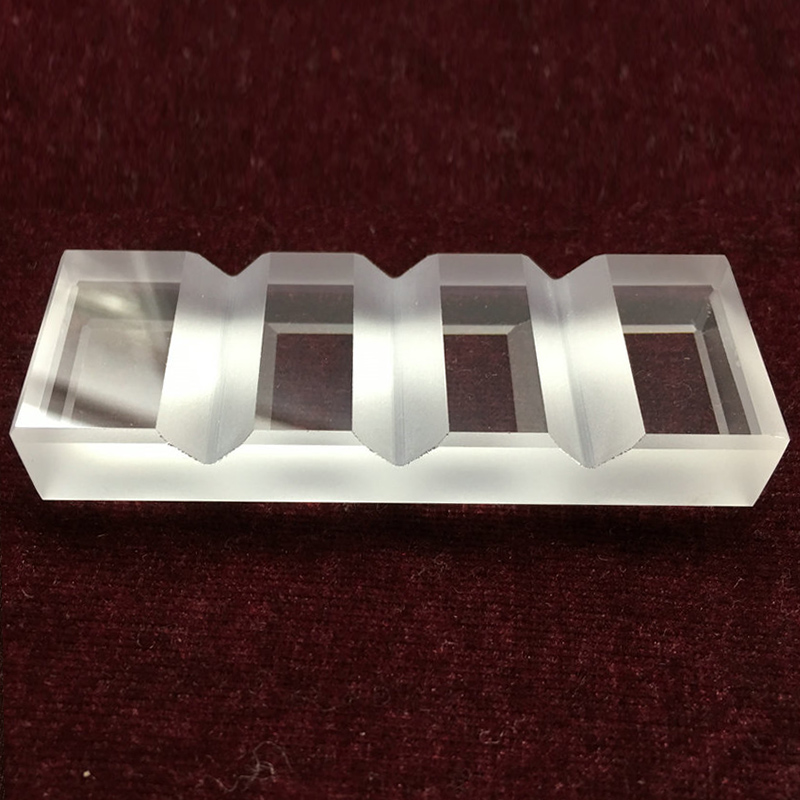

Heavy Wall Quartz Sleeves are robust, thicker-than-standard quartz tubes specifically engineered for demanding applications that require enhanced mechanical strength, pressure resistance, and superior physical durability. Unlike thin-walled quartz tubing primarily used for internal processes, these heavy wall sleeves are commonly employed as protective jackets for sensitive components, such as UV sterilization lamps, heating probes, thermocouples, or in industrial processes involving high differential pressures. The increased wall thickness significantly boosts the sleeve's resistance to external impacts, sudden pressure changes, and aggressive flow rates of liquids or gases. Yancheng Mingyang Quartz Products Co., Ltd. uses high-quality raw material and precision drawing techniques to ensure both the purity of the quartz (≥99.99% SiO2) and the uniformity of the wall thickness, which is paramount for predictable pressure rating and thermal stress distribution.

Our expertise as a quartz tube manufacturer allows us to produce these sleeves with exceptional dimensional consistency, which is vital for proper sealing when integrated into water purification systems or chemical reactors. The low thermal expansion of the fused quartz material, even in a heavy wall configuration, ensures that the sleeve maintains its integrity and dimensional stability across a wide temperature range, minimizing the risk of failure during process start-up or shutdown. Furthermore, the inherent chemical inertness of quartz means these sleeves can reliably protect internal elements from highly corrosive fluids—such as ozone-rich water, strong acids, or concentrated saline solutions—without undergoing degradation or contaminating the surrounding medium. This makes them indispensable in environmental, industrial, and medical sectors where both component protection and process purity are required. We offer various end finishes, including fire-polished ends, precision-ground ends for sealing, and custom drilling or slotting for mounting purposes, tailored exactly to the client's integration needs.

For buyers concerned with longevity and safety in critical infrastructure (like high-pressure water treatment plants), choosing a Heavy Wall Quartz Sleeve ensures a substantial safety margin and extended operational life compared to standard-wall options. We manufacture these sleeves to exceed industry standards, providing the highest reliability.

+86-0515-86223369

+86-0515-86223369  en

en English

English 日本語

日本語 Español

Español