Introduction

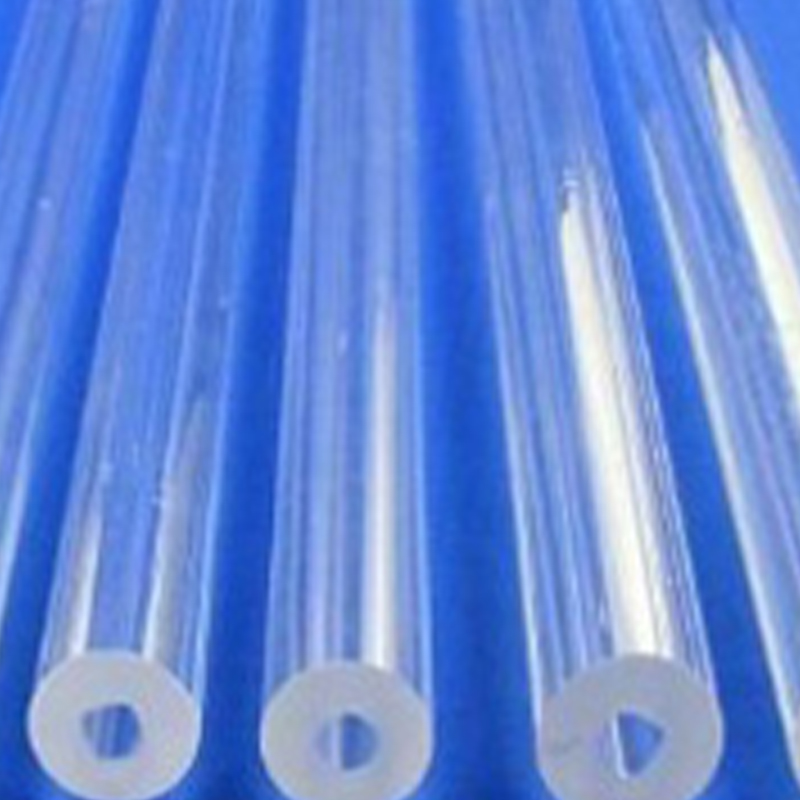

High-Temperature Quartz Seals and Gaskets are specialized components used to create airtight, chemically resistant, and thermally stable interfaces between quartz and other materials (e.g., metal, ceramic) in demanding industrial and laboratory equipment. These components are typically machined or fabricated from solid fused quartz or fused silica tubing, often involving precision grinding and polishing to achieve a flawless sealing surface. Yancheng Mingyang Quartz Products Co., Ltd. provides various types of quartz seals, including flange seals, O-rings, bell jar seals, and specialized dome-to-tube interfaces, which are critical for maintaining vacuum integrity, inert gas environments, or high internal pressure at elevated temperatures. The unique advantage of using quartz for sealing is its incredibly low coefficient of thermal expansion (CTE), which minimizes dimensional change during thermal cycling, ensuring the seal remains intact and reliable under the most challenging thermal gradients.

A common application is in creating seals for High-Vacuum and Ultra-High Vacuum (UHV) systems and Diffusion/CVD furnace end caps. Here, the quartz seal provides a leak-tight barrier that is chemically inert to process gases and stable up to 1100∘C or higher. We employ precision CNC machining to grind sealing faces (e.g., knife-edge seals) to exceptionally high flatness and parallelism tolerances, which ensures optimal compression and mating with standard KF, CF, or custom flanges, often using high-temperature graphite or metal gaskets. For direct sealing applications, we offer specialized quartz-to-metal transition seals where a carefully graded glass/ceramic is used to fuse quartz to a metallic flange (like Kovar or stainless steel). This permanent, reliable transition seal is essential where high mechanical strength and absolute vacuum integrity are required, such as in high-power UV lamp construction or specialized vacuum feedthroughs. We customize the profile (e.g., tapered, stepped, concave, or convex) to match the client's mating surface, providing a critical interface component that is safe and reliable at extreme operating limits.

By focusing on precision grinding and material science, we provide essential quartz seals and gaskets that maintain process integrity in environments where conventional materials would fail due to thermal stress or chemical attack.

+86-0515-86223369

+86-0515-86223369  en

en English

English 日本語

日本語 Español

Español