Introduction

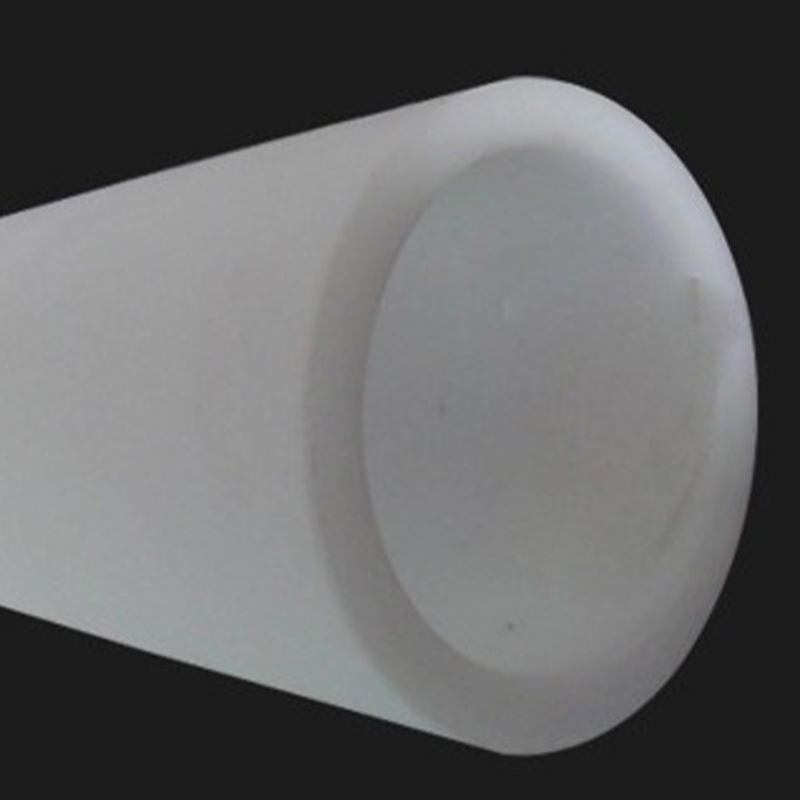

Large Diameter Quartz Pipes are specialized tubing components characterized by outer diameters (OD) typically exceeding 200 mm and often reaching up to 500 mm or more. These pipes are fundamental to applications where large volumes of gas or liquid must be contained or reacted under conditions of high temperature, chemical corrosion, or extreme purity requirements. As a manufacturer controlling the initial draw process, Yancheng Mingyang Quartz Products Co., Ltd. ensures these pipes maintain exceptional dimensional uniformity and low OH content, crucial for minimizing light scattering and maximizing thermal stability in industrial furnaces and reactors. Due to their size, these pipes require expert handling and fabrication. We utilize specialized fusion and annealing processes to mitigate internal stress, ensuring the structural integrity is maintained across the entire large surface area and thick wall profile.

The primary markets for these large pipes include the production of polysilicon and ingots for the photovoltaic (solar) industry, the manufacture of large-area optical fibers, and the creation of large-scale chemical reactor chambers. The high cost of the final product in these fields makes the reliability of the quartz pipe an absolute necessity. Our commitment to using the highest quality fused silica ensures minimal metallic contamination (often ppb level purity), preventing yield-reducing defects in sensitive processes. We offer customization in pipe length, wall thickness, and end finishing—including grinding, polishing, and specialized tapering—to ensure perfect integration into your existing large-scale equipment. For applications requiring specific optical properties, we provide various grades, including opaque or translucent quartz, often used for uniform heat distribution in large furnace environments.

Manufacturing large diameter quartz pipes is technically challenging; maintaining roundness and avoiding defects like bubbles or inclusions requires advanced process control. Our continuous investment in large-scale quartz drawing and processing equipment allows us to reliably meet the high volume and stringent quality demands of the global solar and large-scale material processing sectors. We offer full dimensional and purity certifications with every order, standing behind the quality and performance of these mission-critical components.

+86-0515-86223369

+86-0515-86223369  en

en English

English 日本語

日本語 Español

Español