If you need any help, please feel free to contact us

Web Menu

Product Search

Exit Menu

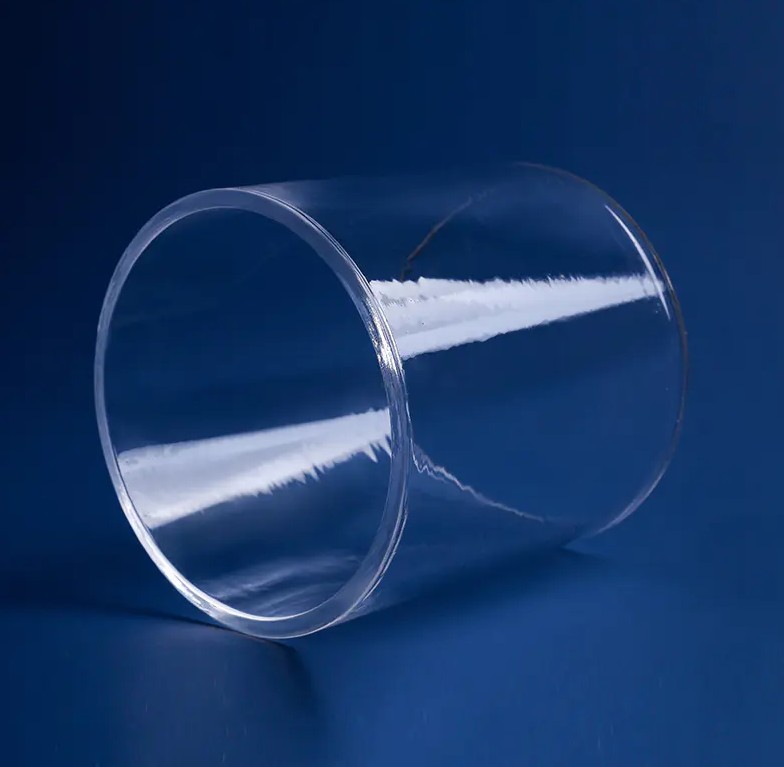

What are the uses of Transparent Glass Tube?

As a high-performance specialty glass product, Transparent Glass Tube plays an indispensable role in modern industry, scientific research, and everyday applications due to its exceptional optical, heat-resistant, and chemical stability. Made primarily from silicon dioxide (SiO2) and boron oxide (B2O3), supplemented with aluminum oxide (Al2O3) and alkali metal oxides, this glass tubing is produced through a special high-temperature melting process. Its unique composition and structure endow it with exceptional properties unmatched by ordinary glass, enabling a wide range of applications.

Content

1. High Light Transmittance

One of the core properties of Transparent Glass Tube is its high light transmittance, reaching up to 92% for visible light. This property makes it an ideal material for optical applications:

Microscopic Observation and Spectroscopic Analysis: In laboratories, Transparent Glass Tube is often used to manufacture cuvettes, absorption cells, and optical windows, ensuring the unimpeded passage of light. This makes it suitable for high-precision spectral analysis, photometry, and microscopic observation of samples. Its exceptional optical clarity is crucial for accurate scientific experimental results.

2. Temperature Resistance

Thanks to a low coefficient of thermal expansion of (3.3±0.1)×10⁻⁶/K, Transparent Glass Tube offers remarkable temperature resistance.

Resistant to Extreme Temperature Differences: This glass tubing can withstand extreme temperature swings from -50°C to 500°C, three times the temperature resistance of ordinary glass, and will not deform or crystallize at high temperatures. This makes it ideal for use as heat-resistant glass tubing in chemical reactor windows, high-temperature fluid transfer systems, and heat exchange equipment.

3. Chemical Stability

Transparent Glass Tube exhibits excellent chemical resistance, withstanding corrosion from strong acids and bases, with the exception of hydrofluoric acid and hot phosphoric acid.

Contamination-Free Transmission: It maintains its permeability and structural integrity even after prolonged immersion. Therefore, it is often used for the storage and transport of high-purity reagents, corrosive chemicals, and biological samples, effectively preventing contamination of experimental samples or industrial materials by the container, thus ensuring the purity of experiments or production.

4. Mechanical Strength and Precision Manufacturing

Transparent glass tubing also features high mechanical strength and strong pressure resistance, allowing for extremely precise processing.

Ultrafine capillaries: They can be processed into capillaries with extremely fine inner diameters (e.g., 0.6mm). These precision tubing components are widely used in biomedicine, microfluidic chips, and microreactors. For example, in life science research, ultrafine glass capillaries are used in precision applications such as single-cell capture, microinjection, and drug screening, making them essential tools for modern bioengineering and chemical analysis.

Transparent glass tubing is not only a fundamental material but also a key component for breakthroughs in numerous high-tech fields. Whether it's optical instruments requiring high light transmittance, industrial equipment requiring high-temperature resistance, or precision analytical tools requiring high chemical stability and mechanical strength, transparent glass tubing, with its excellent comprehensive performance, provides a reliable and efficient solution. Choosing high-quality transparent glass tubes means choosing higher experimental accuracy and more stable industrial operation.

- Tel:

+86-0515-86223369

+86-15754187666 - WeChat:

+86-13485219766 - WhatsApp:

+86-13485219766 - E-mail:

[email protected]

[email protected] - Add:

NO.33,yuejinRoad,Science And Technology Pioneer Park,hengji Town,jiangsu county,yancheng city,jiangsu province,china 224763, China

Copyright © Yancheng Mingyang Quartz Products Co., Ltd. All Rights Reserved.

Wholesale Quartz Products Manufacturer Quartz Glass Factory

+86-0515-86223369

+86-0515-86223369  en

en English

English 日本語

日本語 Español

Español