If you need any help, please feel free to contact us

High Borosilicate Experimental Equipment Supplier

Overview of high borosilicate glass tube

A high borosilicate glass tube is a high-performance glass material made of silicon dioxide (SiO₂) and boron oxide (B₂O₃) as the main components, supplemented by a small amount of aluminum oxide (Al₂O₃), alkali metal oxides (such as Na₂O, K₂O), and other raw materials. The production process includes raw material pretreatment, melting, molding, annealing, and post-processing. Among them, high-temperature melting technology (such as electric melting furnaces) can improve the uniformity and stability of the material. 35.

Core characteristics

Heat resistance and low expansion

The linear thermal expansion coefficient is as low as (3.3±0.1)×10⁻⁶/K, which can withstand high temperature changes (such as laboratory heating, solar heat collection) without breaking easily. 37.

Chemical stability

Resistant to acid and alkali corrosion (except hydrofluoric acid and hot phosphoric acid), suitable for harsh environments such as chemical pipelines and pharmaceutical packaging; the surface is smooth and non-porous, which can reduce material deposition and pollution. 57.

Optical and mechanical properties

High transmittance makes it easy to observe the experiment or production process; high strength and hardness make it suitable for making precision instruments and pressure-resistant equipment37.

Application areas

Laboratory and scientific research: used for chemical instruments, reaction vessels, and experimental consumables to meet the needs of high-temperature and high-purity experiments34.

Solar energy utilization: as the core material of vacuum collector tubes, it absorbs and converts solar energy to improve the efficiency of water heaters6.

Chemical and pharmaceutical: corrosion-resistant pipes, pharmaceutical containers, and food testing equipment to avoid heavy metal precipitation and chemical reactions57.

Industrial and civil: manufacturing craft glass products (such as tea sets, lamps), energy-saving lamps, etc., which are both functional and aesthetic37.

Production process optimization

Raw material processing: acid leaching and iron ion collectors (such as tannic acid/polyacrylamide hydrogel) are used to remove quartz sand impurities and improve transmittance1.

Coloring technology: Cobalt blue pigment is wrapped by mesoporous silica, combined with silane coupling agent and borate modification to achieve color stability at high temperature2.

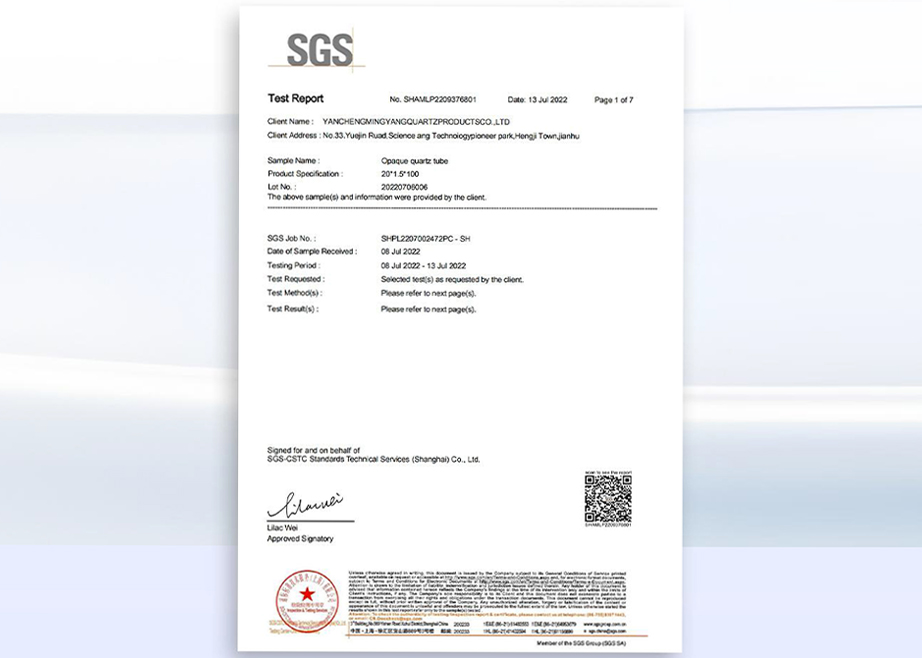

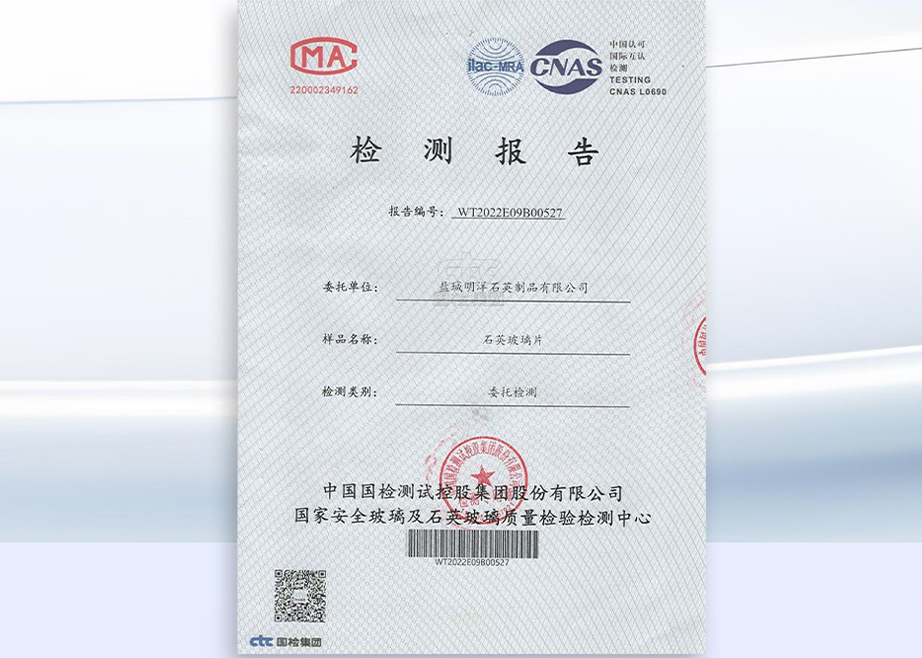

Quality control: The company introduces a fully automatic electric melting furnace and online detection system to ensure product consistency and reliability

Global Smart Manufacturing

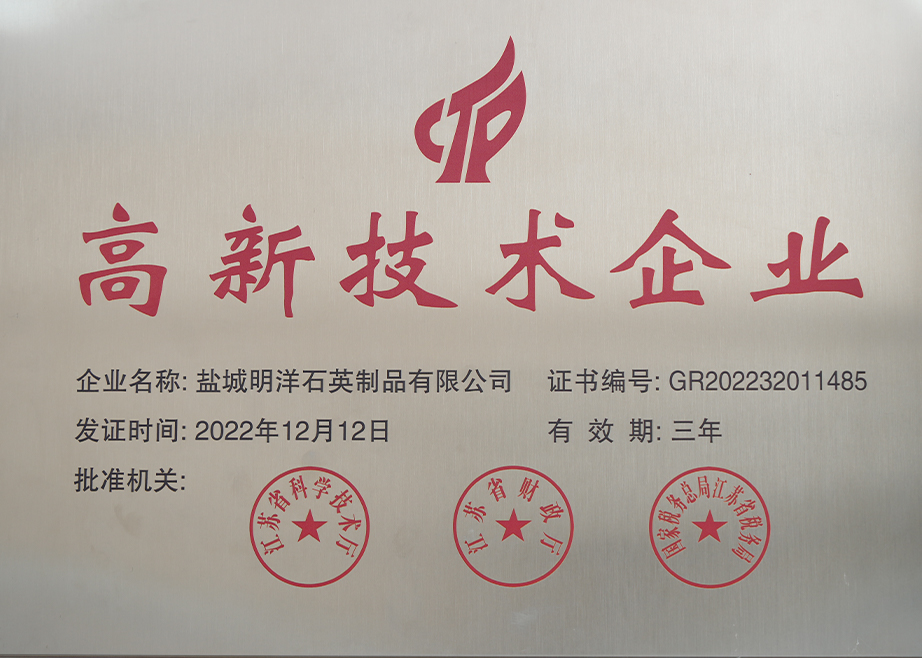

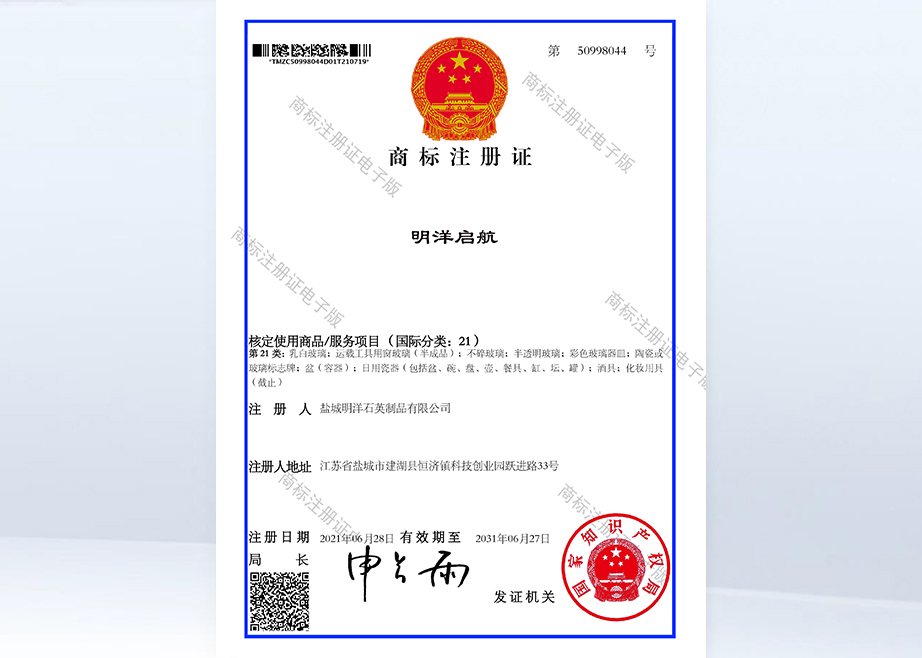

Yancheng Mingyang Quartz Products Co., Ltd. is a company specializing in the production of quartz and special glass products. Yancheng Mingyang Quartz Products Co., Ltd. is the production plant of Jinzhou Mingde Quartz Glass Co., Ltd. in Jiangsu, We are a professional custom High Borosilicate Experimental Equipment Supplier and High Borosilicate Experimental Equipment Factory. Since its establishment, the company has developed rapidly, introduced advanced technology and production equipment at home and abroad, and continuously improved and improved product quality. Relying on its own advantages, we have developed a variety of products suitable for the market and meet the needs of different customers, and solved many urgent production problems for our customers.

The company's products include quartz glass tubes, double-hole quartz glass tubes, quartz glass rods, quartz sheets, sapphire windows, calcium fluoride glass windows, infrared ultraviolet coatings, high-pressure resistant aluminosilicate glass window panels, quartz glass instruments, high borosilicate glass instruments, quartz crucibles, quartz gold-plated tubes, quartz heaters, quartz infrared heating tubes, far-infrared directional radiation heaters ultraviolet germicidal lamps and other special types of quartz glass products.

-

Key Conclusion: Why are quartz tubes an irreplaceable material in industry? With its near 100% silica purity, Quartz Tubes exhibit superior ...

READ MORE -

Essentially, a quartz crucible is a high-grade form of a silica crucible; both have silica as their core chemical component. However, in ind...

READ MORE -

Quartz cuvettes are key components widely used in spectroscopic analysis experiments. Their primary purpose is as sample containers, holding...

READ MORE -

The working principle of a quartz heating tube mainly utilizes a specially made milky white or transparent quartz glass tube as the outer sh...

READ MORE -

In the high-performance glass market, Quartz Glass Plate, with their superior physical and chemical properties, have become important materi...

READ MORE

High borosilicate experimental equipment is a high-performance experimental equipment made of high borosilicate glass tube as the core material. The main components are silicon dioxide and boron oxide, supplemented by a small amount of aluminum oxide and alkali metal oxides. This material is produced by high-temperature melting and precision annealing technology. It has excellent heat resistance, chemical stability, mechanical strength and optical properties. It is widely used in laboratories, chemicals, pharmaceuticals, solar energy utilization and industrial and civil fields.

We are a high-tech enterprise specializing in the production of quartz and special glass products, integrating R&D, production and sales. Since its establishment, the company has developed rapidly, introduced advanced technologies and production equipment from home and abroad, established a strict quality control system, and continuously improved production processes to enhance product performance. Relying on strong technical strength and rich industry experience, we have developed a variety of high borosilicate glass, quartz glass and special glass products, which are widely used in laboratories, chemicals, photovoltaics, semiconductors, optics and other fields.

With excellent product quality and rapid response capabilities, we have provided many customers with high-purity, high-temperature resistant and corrosion-resistant glass solutions, and successfully assisted customers in solving many urgent production problems, winning wide recognition in the market.

The linear thermal expansion coefficient of high borosilicate experimental equipment is as low as (3.3±0.1)×10⁻⁶/K. It can withstand drastic temperature changes (such as high temperature heating and sudden cooling) to avoid cracking due to thermal stress. It is suitable for laboratory heating, high temperature reaction and other scenarios. It is resistant to strong acids and alkalis and is suitable for corrosive media. The surface is smooth and non-porous, reducing the deposition of pollutants and ensuring the purity of the experiment.

The high borosilicate experimental equipment has high light transmittance, which is convenient for observing the experimental process and is suitable for optical instruments and reaction monitoring. With high strength and hardness, it can be made into precision instruments and pressure-resistant containers (such as vacuum collectors and high-pressure reactors).

With its excellent physical and chemical properties, high borosilicate glass has shown a wide range of application value in many fields. In the field of laboratories and scientific research, it is widely used to manufacture various chemical instruments, such as conventional experimental utensils such as beakers, test tubes, condensers, as well as various reaction vessels and high-purity experimental consumables. These products can perfectly meet the laboratory's needs for high-temperature operating environments, while ensuring that the experimental process is not contaminated, providing reliable hardware support for scientific research.

In terms of solar energy utilization, high borosilicate glass has become the core material of vacuum solar collector tubes due to its excellent thermal stability and light transmittance. This material can efficiently absorb and convert solar energy, significantly improve the thermal efficiency of equipment such as solar water heaters, and provide important support for the development and utilization of clean energy.

The chemical and pharmaceutical industries also have a strong demand for high borosilicate glass. Due to its excellent corrosion resistance, it is widely used in the manufacture of chemical pipelines, drug storage containers, and food testing equipment. These applications can not only effectively avoid the precipitation of heavy metals, but also prevent pollution caused by various chemical reactions, ensuring the purity and safety of the production process.

In the industrial and civil fields, high borosilicate glass also shows unique value. It is used to manufacture various high-end craft glass products, such as exquisite tea sets and lamps, which not only meet functional needs, but also have aesthetic value. In addition, in the field of energy-saving lighting, lamps made of high borosilicate glass are also popular for their excellent performance. These diverse applications fully demonstrate the broad market prospects of high borosilicate glass as a special functional material.

+86-0515-86223369

+86-0515-86223369  en

en English

English 日本語

日本語 Español

Español