If you need any help, please feel free to contact us

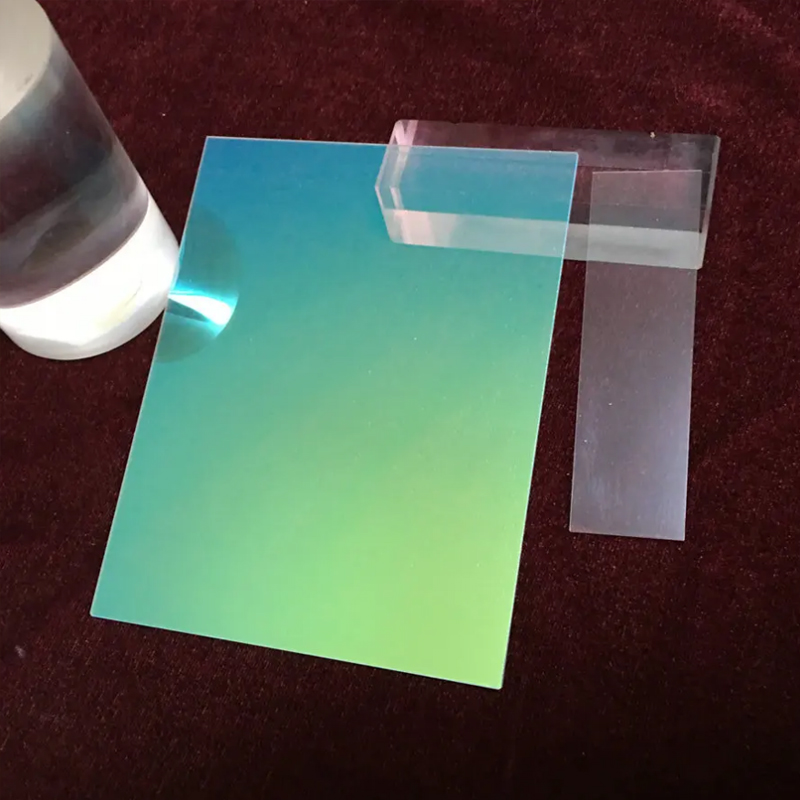

Quartz Glass Sheet Supplier

The formation of quartz glass plate is the result of the high viscosity of its melt at high temperatures. It is widely used in the production of semiconductors, electric light sources, semiconductor communication devices, lasers, optical instruments, laboratory instruments, electrical equipment, medical equipment, high-temperature and corrosion-resistant chemical instruments, the chemical industry, electronics, metallurgy, building materials, and defense industries.

Global Smart Manufacturing

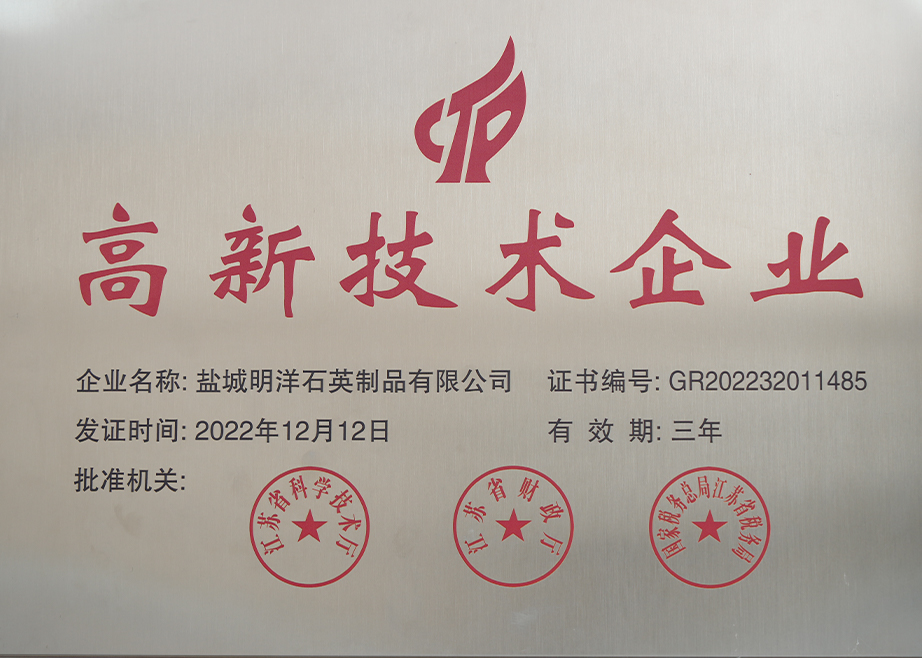

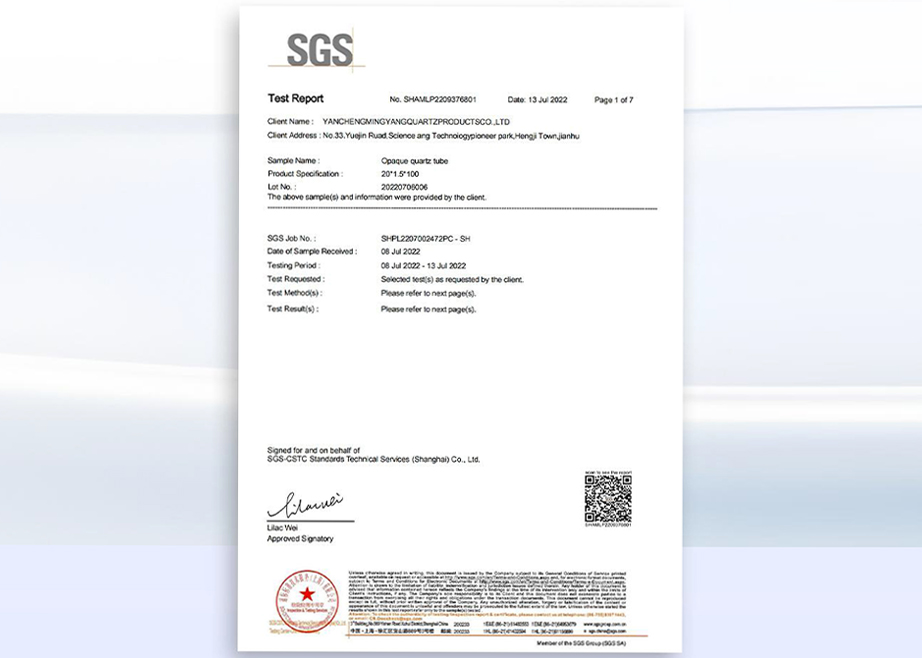

Yancheng Mingyang Quartz Products Co., Ltd. is a company specializing in the production of quartz and special glass products. Yancheng Mingyang Quartz Products Co., Ltd. is the production plant of Jinzhou Mingde Quartz Glass Co., Ltd. in Jiangsu, We are a professional custom Quartz Glass Sheet Supplier and Quartz Glass Window Factory. Since its establishment, the company has developed rapidly, introduced advanced technology and production equipment at home and abroad, and continuously improved and improved product quality. Relying on its own advantages, we have developed a variety of products suitable for the market and meet the needs of different customers, and solved many urgent production problems for our customers.

The company's products include quartz glass tubes, double-hole quartz glass tubes, quartz glass rods, quartz sheets, sapphire windows, calcium fluoride glass windows, infrared ultraviolet coatings, high-pressure resistant aluminosilicate glass window panels, quartz glass instruments, high borosilicate glass instruments, quartz crucibles, quartz gold-plated tubes, quartz heaters, quartz infrared heating tubes, far-infrared directional radiation heaters ultraviolet germicidal lamps and other special types of quartz glass products.

-

Key Conclusion: Why are quartz tubes an irreplaceable material in industry? With its near 100% silica purity, Quartz Tubes exhibit superior ...

READ MORE -

Essentially, a quartz crucible is a high-grade form of a silica crucible; both have silica as their core chemical component. However, in ind...

READ MORE -

Quartz cuvettes are key components widely used in spectroscopic analysis experiments. Their primary purpose is as sample containers, holding...

READ MORE -

The working principle of a quartz heating tube mainly utilizes a specially made milky white or transparent quartz glass tube as the outer sh...

READ MORE -

In the high-performance glass market, Quartz Glass Plate, with their superior physical and chemical properties, have become important materi...

READ MORE

Since its establishment, we have always focused on the research and development and production of high-end quartz glass materials. With advanced technical strength and strict quality management system, we have rapidly developed into an industry-leading supplier of quartz glass products. The company has introduced advanced production equipment and precision testing instruments from home and abroad, combined with independent research and development of innovative processes, to continuously optimize product performance, improve production efficiency and product quality.

Relying on a strong technical team and rich industry experience, we have developed a variety of high-performance quartz glass products, including quartz glass plates, quartz glass windows, fused quartz plates, etc., which are widely used in semiconductors, optics, chemicals, medical, national defense and scientific research. We are always customer-oriented and provide customized solutions to help customers overcome production problems and ensure the stability and reliability of products in extreme environments.

Quartz glass plates are high-performance glass materials made by melting high-purity silicon dioxide. Because its melt has extremely high viscosity at high temperatures, it can form excellent thermal stability and chemical stability. Our quartz glass plates, quartz glass windows, fused quartz plates and other products are widely used in high-tech fields such as semiconductors, electric light sources, optical instruments, lasers, semiconductor communication devices, etc. due to their excellent performance. They also play an important role in industries such as chemicals, electronics, metallurgy, building materials, defense industry and medical equipment.

Ultra-high purity and high temperature resistance: The use of high-purity raw materials ensures that quartz glass plates and fused quartz plates have extremely low thermal expansion coefficients, can withstand high temperatures above 1200°C for a long time, and are suitable for extreme industrial environments.

Excellent optical properties: Quartz glass windows have extremely high transmittance in the ultraviolet (UV) to infrared (IR) bands, and are ideal for optical instruments, laser systems, and precision experimental equipment.

Excellent chemical stability: Resistant to strong acids, strong alkalis and various corrosive media, suitable for harsh environments such as high-purity chemical processing and semiconductor etching.

High mechanical strength: Through special tempering process (optional), the impact resistance and bending strength of quartz glass can be significantly improved to meet the needs of high-pressure and high-load applications.

Precision processing capabilities: support customized size, shape, polishing and coating treatment to ensure the perfect match between the product and the customer's equipment.

Quartz glass plates are suitable for semiconductor manufacturing (lithography machines, etching equipment), high-temperature observation windows, precision instrument substrates, etc. Precision polished versions with high flatness and low defect rates are available.

Quartz glass windows are used for laser windows, optical sensors, vacuum cavity observation windows, spacecraft high-temperature windows, etc. Optional surface treatments such as anti-reflection film (AR) and hard coating can be used to improve optical performance. Fused quartz plates are ultra-high purity, low in bubbles and impurities, and are suitable for high-end semiconductors and precision optical components. Tempered quartz glass is enhanced in impact resistance through thermal or chemical tempering processes, and is suitable for special scenarios such as high-voltage equipment and explosion-proof observation windows.

Application areas of quartz glass plates:

Semiconductor and electronics industries: wafer processing, lithography machine components, plasma etching equipment, integrated circuit manufacturing.

Optical and laser technology: lenses, prisms, laser resonators, UV curing equipment, infrared detection systems.

Chemical and medical equipment: corrosion-resistant reactor windows, high-purity drug production, medical laser therapy devices.

New energy and aerospace: solar panel coating equipment, spacecraft high-temperature windows, high-energy physics experimental equipment.

National defense and scientific research: missile seeker optical components, nuclear industry observation equipment, precision laboratory instruments.

We continue to introduce international advanced technologies, combined with independent innovation, to ensure that product performance is industry-leading. From raw material screening to finished product delivery, the whole process is precisely tested to ensure the reliability of each piece of quartz glass. Provide emergency order services to help customers solve sudden production needs. According to customer application scenarios, provide full-range support such as material selection, size customization, and surface treatment.

+86-0515-86223369

+86-0515-86223369  en

en English

English 日本語

日本語 Español

Español