If you need any help, please feel free to contact us

Quartz Carbon Fiber Heating

InquiryThe combination of quartz and carbon fiber

The integration of carbon fibers into quartz tubes can enhance the performance of heating systems, especially in applications where high-temperature stability and fast response are required. As an excellent insulating and high-temperature resistant material, quartz can protect the carbon fiber heating element and allow infrared rays to pass through.

advantage

Energy-efficient

The carbon fiber heater has a high conversion efficiency, which can quickly reach the set temperature and maintain a constant output, reducing energy loss.

Heats up quickly

Quartz carbon fiber heaters provide a rapid ramp-up in a short period of time and are ideal for applications that require instant heating.

Heat evenly

The carbon fiber is evenly distributed, resulting in a more balanced heat distribution and avoiding local overheating.

Long life

Quartz tubes provide good physical protection, while the carbon fiber itself has a long service life, reducing maintenance costs.

Safe and reliable

Quartz material has excellent electrical insulation properties, reducing the risk of leakage; Carbon fiber, on the other hand, is less flammable, improving overall safety.

Environmentally friendly and healthy

Far infrared rays are believed to be beneficial to the human body, helping to improve blood circulation, relieve muscle pain, etc., without producing harmful gases.

Fields of application

Industrial heating

Drying and curing: It is used for the rapid drying of paints, inks, and other materials, as well as the curing of plastics, wood, and other products.

Food processing: Heating sources in ovens, barbecue equipment, providing uniform and controlled heat.

agriculture

Greenhouse heating provides the necessary temperature conditions for plant growth, especially in the cold season.

Animal breeding: Maintain the right temperature in the barn to promote the healthy growth of animals.

Healthcare

Physiotherapy equipment: used to relieve muscle pain, arthritis, and other symptoms and promote blood circulation.

Disinfection and sterilization: Some types of infrared light have a sterilization and disinfection effect.

Commercial premises

Outdoor district heating: Provide a comfortable heating experience for outdoor seating areas in restaurants, cafes, and more.

Exhibition display: Maintain the best display conditions of exhibits and prevent moisture damage.

Home use

Indoor heating: As an energy-saving and environmentally friendly heating method, it is especially suitable for local area heating.

Bathroom Drying: Prevents dampness in the bathroom and reduces mold growth.

Technical Specifications of Heating Element

| Parameter | Specification | Parameter | Specification |

|---|---|---|---|

| Rated Voltage (V) | 24, 36, 72, 100, 110, 115, 120, 220, 230, 235, 240, 380 | Power Tolerance (%) | +5 ~ -10 |

| Power Rating (W) | 70 - 5,000 | Length Tolerance (mm) | ±2 |

| Tube Length (mm) | 100 - 3,000 | Diameter Tolerance (mm) | ±0.5 |

| Outer Diameter Φ (mm) | 8, 10, 12, 16, 19 | Max. Operating Temp. (°C) | 800 |

| Electrical-Thermal Efficiency (%) | ≥98% | Max. Surface Temp. (°C) | 900 |

| Thermal Radiation Efficiency (%) | ≥75% | IR Wavelength Range (μm) | 1.5 - 15 |

| Normal Total Emissivity (%) | ≥88% | Design Life (hours) | 6,000 |

| Color Temperature (K) | 800 - 1,500 |

Transparent quartz glass properties

| Property | MQ - T100 MQ - T101 MQ - T102 |

MQ - T110 MQ - T111 MQ - T112 |

MQ - R300 MQ - R400 |

MQ - R200 |

|---|---|---|---|---|

| Density | 2.2×10³kg/m³ | 2.2×10³kg/m³ | 2.22×10³kg/m³ | 2.21×10³kg/m³ |

| Hardness | 570KHN₀.₀₀ | 580KHN₀.₀₀ | 585KHN₀.₀₀ | 580KHN₀.₀₀ |

| Tensile Strength | 4.8×10⁸Pa(N/m²) | 4.9×10⁸Pa(N/m²) | 5.0×10⁸Pa(N/m²) | 4.9×10⁸Pa(N/m²) |

| Compression Strength | >1.1×10⁹Pa | >1.1×10⁹Pa | >1.1×10⁹Pa | >1.1×10⁹Pa |

| Coefficient of Thermal Expansion (20°C - 300°C) | 5.5×10⁻⁷cm/cm°C | 5.5×10⁻⁷cm/cm°C | 5.5×10⁻⁷cm/cm°C | 5.5×10⁻⁷cm/cm°C |

| Thermal Conductivity (20°C) | 1.4W/m°C | 1.4W/m°C | 1.4W/m°C | 1.4W/m°C |

| Specific Heat (20°C) | 660J/kg°C | 670J/kg°C | 680J/kg°C | 680J/kg°C |

| Softening Point | 1630°C | 1680°C | 1690°C | 1700°C |

| Annealing Point | 1180°C | 1215°C | 1220°C | 1210°C |

From quotation to delivery, we provide one-stop customer service, responding quickly to customer needs, solving problems efficiently, and completing shipments. Additionally, we offer process optimization and technical support services, including professional workflow improvement, sample preparation and testing, mass production supply, and technical assistance. We meet customers' demands for quartz and specialty glass products.

-

Materials Design

Materials Design

And DevelopmentWe can design and develop quartz and specialty glass according to customer needs and application requirements.

-

Manufacturing Process

Manufacturing Process

OptimizationThe manufacturing process of quartz and specialty glass can be optimized for customers.

-

Sample Preparation

Sample Preparation

And TestingWe provide sample preparation and testing services for new types of quartz and specialty glass.

-

Mass Production

Mass Production

And SupplyOnce approved, quartz and specialty glass can be mass-produced to ensure stable and reliable supply.

-

Technical Support

Technical Support

And ConsultingMingyang can also provide relevant technical support and consulting services to customers.

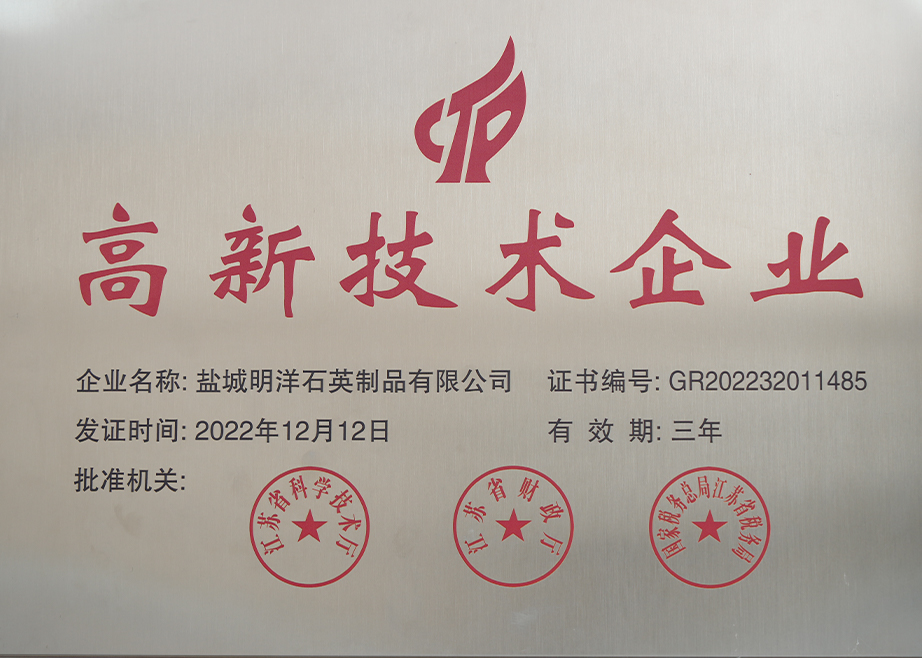

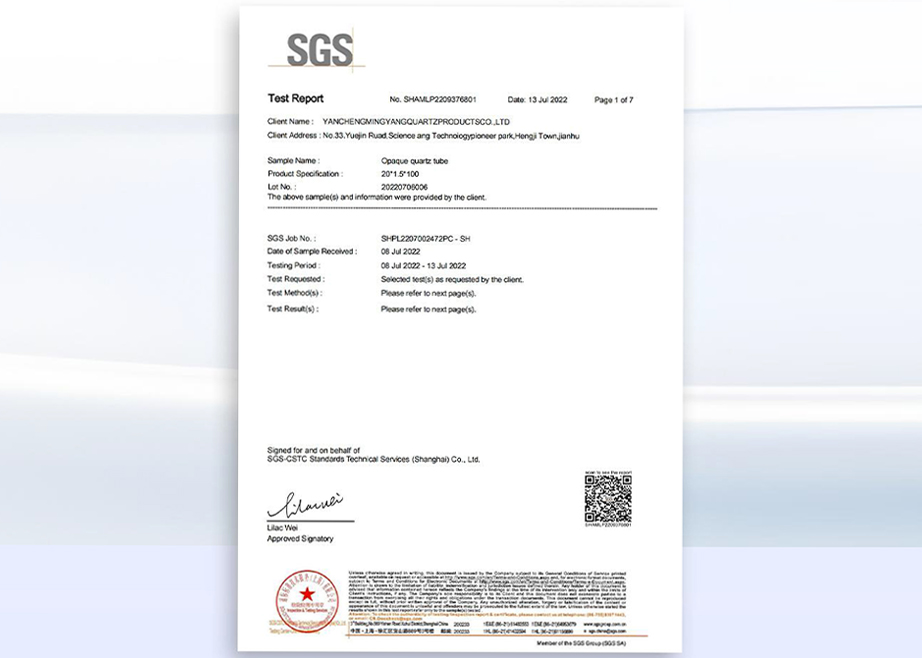

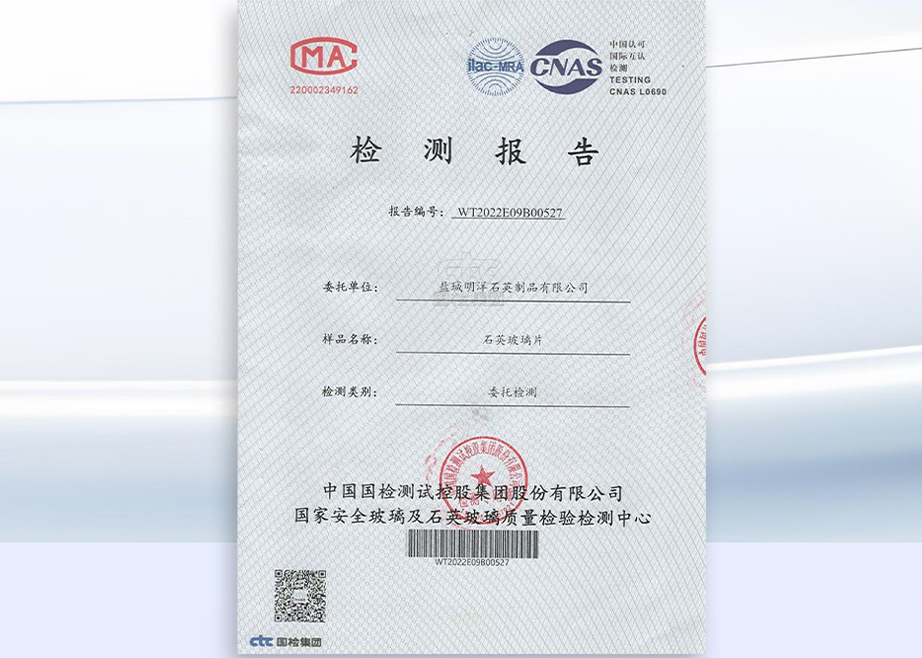

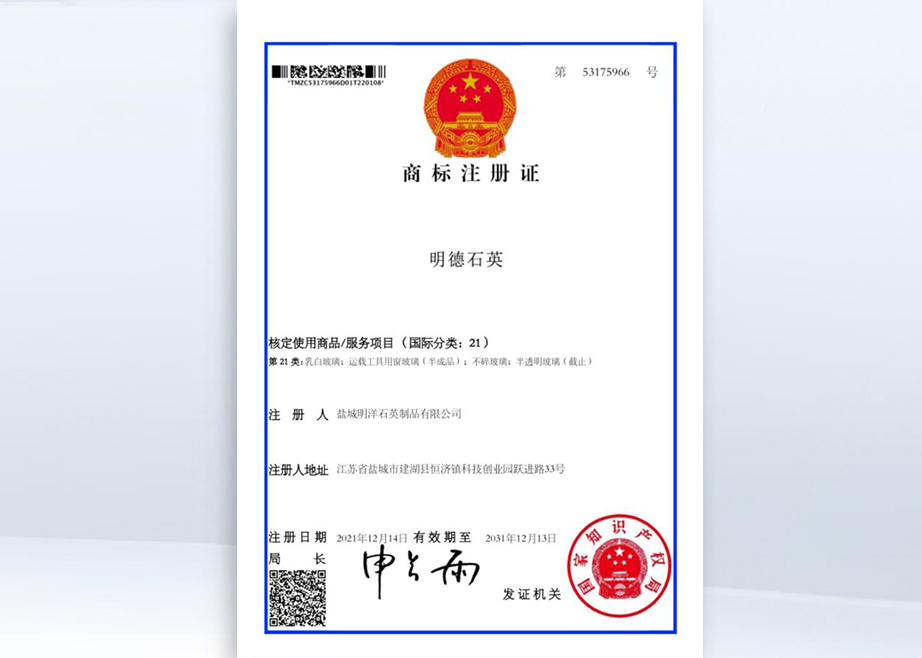

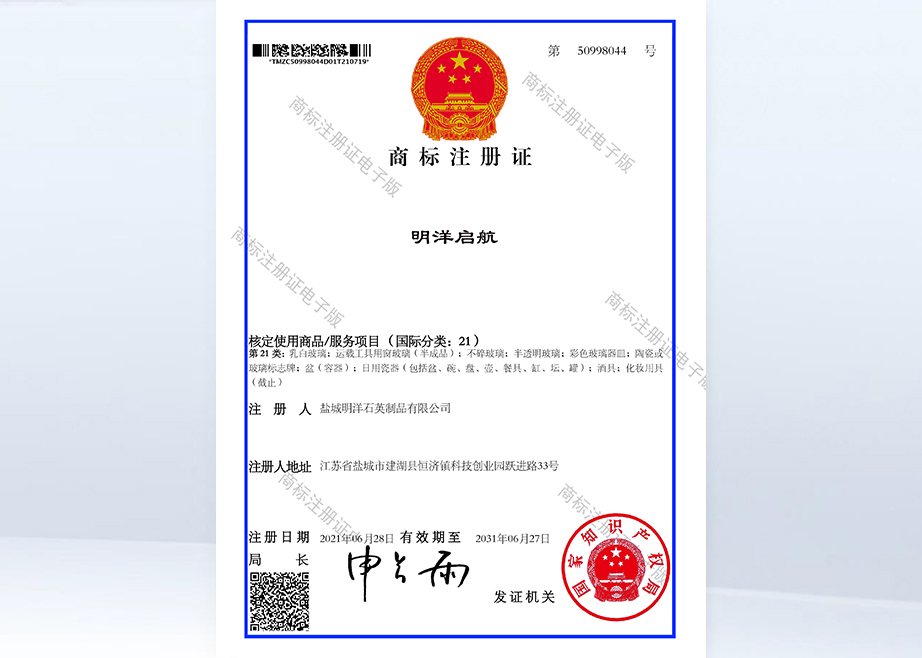

Global Smart Manufacturing

Yancheng Mingyang Quartz Products Co., Ltd. is a company specializing in the production of quartz and special glass products. Yancheng Mingyang Quartz Products Co., Ltd. is the production plant of Jinzhou Mingde Quartz Glass Co., Ltd. in Jiangsu, We are a professional OEM Quartz Carbon Fiber Heating Manufacturers and Quartz Carbon Fiber Heating Manufacturers. Since its establishment, the company has developed rapidly, introduced advanced technology and production equipment at home and abroad, and continuously improved and improved product quality. Relying on its own advantages, we have developed a variety of products suitable for the market and meet the needs of different customers, and solved many urgent production problems for our customers.

The company's products include quartz glass tubes, double-hole quartz glass tubes, quartz glass rods, quartz sheets, sapphire windows, calcium fluoride glass windows, infrared ultraviolet coatings, high-pressure resistant aluminosilicate glass window panels, quartz glass instruments, high borosilicate glass instruments, quartz crucibles, quartz gold-plated tubes, quartz heaters, quartz infrared heating tubes, far-infrared directional radiation heaters ultraviolet germicidal lamps and other special types of quartz glass products.

+86-0515-86223369

+86-0515-86223369  en

en English

English 日本語

日本語 Español

Español