If you need any help, please feel free to contact us

Transparent Quartz Tube Double Tube

InquiryThe transparent quartz tube double tube uses high-purity silicon dioxide as the core raw material, with SiO₂ content exceeding 99.9% and extremely low impurity content, which ensures the long-term stability of the material from the source. It has high geometric dimensional accuracy and uniform tube wall thickness, which can meet the stringent requirements of precision machining and complex working conditions, and provide a reliable foundation for the efficient operation of the equipment.

The product has strong resistance to thermal deformation and can withstand extreme temperature changes, such as sudden cooling and heating, avoiding cracking or deformation caused by thermal stress.

| Category | Details |

| Product Name | Clear large diameter quartz glass tube |

| Application | Heater |

| Outside Diameter | 3 - 450mm |

| Place of Origin | Jiangsu, China |

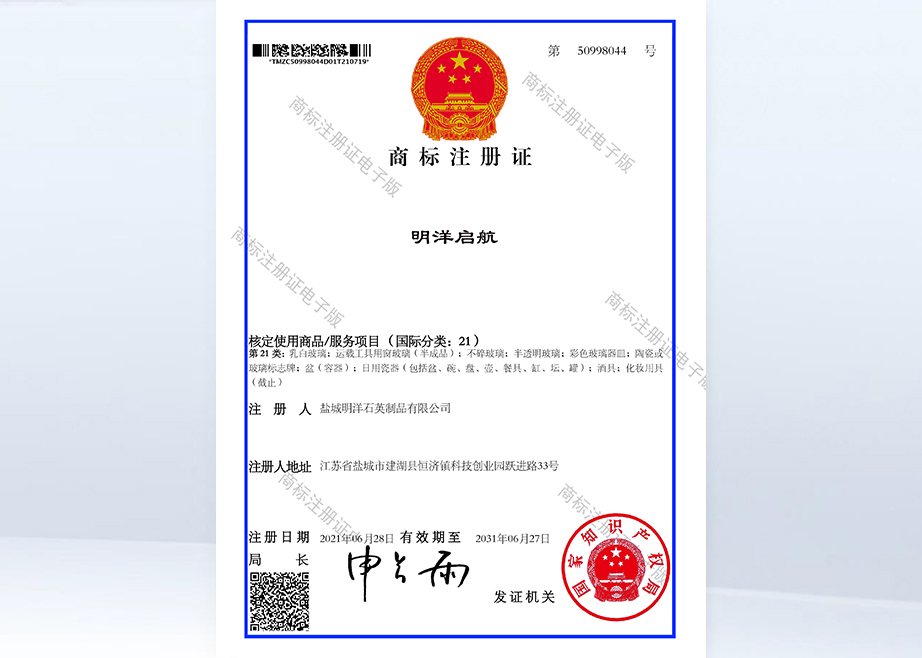

| Brand Name | Mingyang Quartz Glass Tube |

| Model Number | Quartz Glass Test Tube |

| Color | Opaque/clear |

| Surface Treatment | Grinded |

| Shape | One End Closed Quartz Tube |

| Ozone Content | Ozone Free |

| Brand | Mingyang Quartz Glass Tube |

| Material | >99.99% SiO₂ |

| Certification | ISO9001 |

| Size | Customized the size of the tube |

| Length | Customized |

| Density | 2.2g/cm³ |

| Available Shape | Both ends open tube, one end closed tube |

| Operating Temperature | 1250℃ |

| Package | Standard Export Packing |

MQ-R100 Translucent quartz tube general dimensions and tolerance

|

Designation |

OD |

Wall |

Length |

Max.Siding |

Max.Ovality |

Max.Bow |

|

5-8 |

±0.25 |

±0.10 |

±1.0 |

0.10 |

0.20 |

2% |

|

8-12 |

±0.30 |

±0.10 |

±1.0 |

0.15 |

0.20 |

2% |

|

12-15 |

±0.40 |

±0.15 |

±1.0 |

0.20 |

0.30 |

2% |

|

15-20 |

±0.50 |

±0.15 |

±1.0 |

0.20 |

0.40 |

2% |

|

20-30 |

±0.80 |

±0.20 |

±1.0 |

0.30 |

0.50 |

3% |

Translucent quartz glass properties

|

Property |

MQ-R100 |

MQ-R300/R400 |

|

Density |

1.92×103kg/m3 |

1.95×103kg/m3 |

Compression Strength |

>1.0×10 °Pa(N/m2) |

>1.0×10 °Pa(N/m2) |

|

Coefficient of Thermal Expansion |

5.4×10-7cm/cm℃ |

5.4×10-7cm/cm℃ |

|

Thermal Conductivity |

Low |

Low |

|

Specific Heat |

640J/kg℃ |

650J/kg℃ |

|

Softening Point |

1580℃ |

1600℃ |

|

Annealing Point |

1050℃ |

1100℃ |

From quotation to delivery, we provide one-stop customer service, responding quickly to customer needs, solving problems efficiently, and completing shipments. Additionally, we offer process optimization and technical support services, including professional workflow improvement, sample preparation and testing, mass production supply, and technical assistance. We meet customers' demands for quartz and specialty glass products.

-

Materials Design

Materials Design

And DevelopmentWe can design and develop quartz and specialty glass according to customer needs and application requirements.

-

Manufacturing Process

Manufacturing Process

OptimizationThe manufacturing process of quartz and specialty glass can be optimized for customers.

-

Sample Preparation

Sample Preparation

And TestingWe provide sample preparation and testing services for new types of quartz and specialty glass.

-

Mass Production

Mass Production

And SupplyOnce approved, quartz and specialty glass can be mass-produced to ensure stable and reliable supply.

-

Technical Support

Technical Support

And ConsultingMingyang can also provide relevant technical support and consulting services to customers.

Global Smart Manufacturing

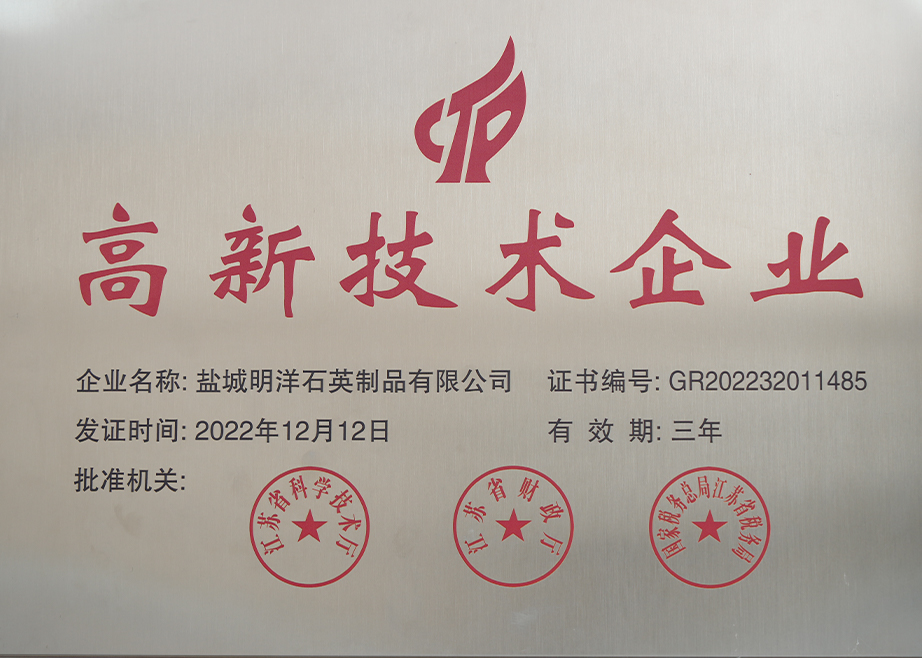

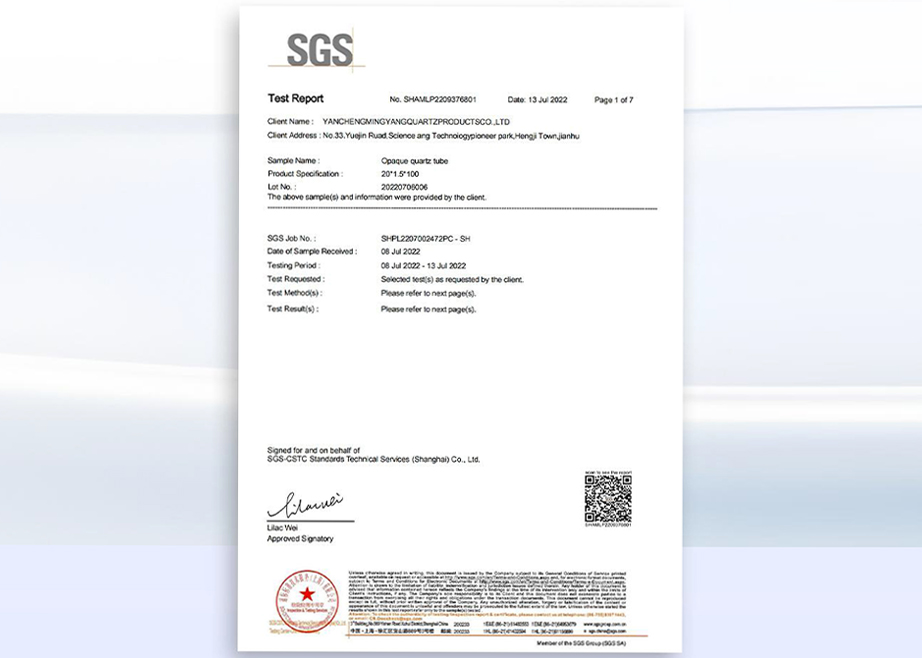

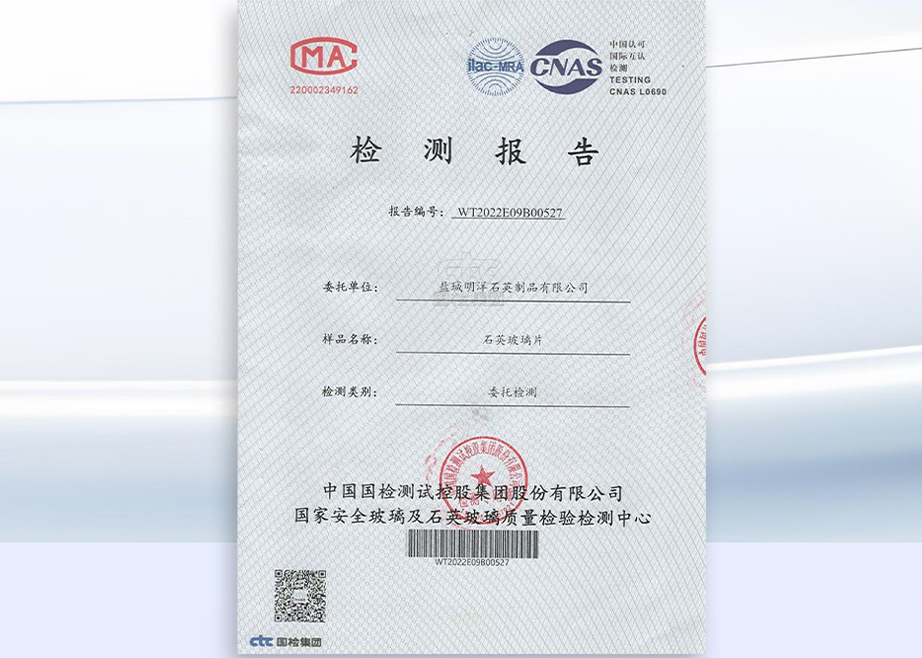

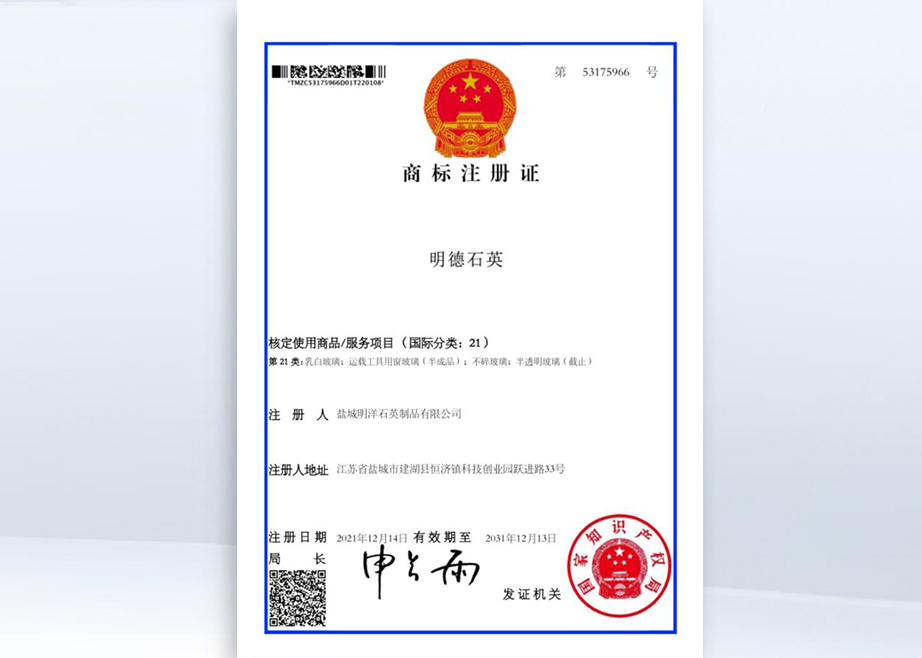

Yancheng Mingyang Quartz Products Co., Ltd. is a company specializing in the production of quartz and special glass products. Yancheng Mingyang Quartz Products Co., Ltd. is the production plant of Jinzhou Mingde Quartz Glass Co., Ltd. in Jiangsu, We are a professional OEM Transparent Quartz Tube Double Tube Manufacturers and Transparent Quartz Tube Double Tube Manufacturers. Since its establishment, the company has developed rapidly, introduced advanced technology and production equipment at home and abroad, and continuously improved and improved product quality. Relying on its own advantages, we have developed a variety of products suitable for the market and meet the needs of different customers, and solved many urgent production problems for our customers.

The company's products include quartz glass tubes, double-hole quartz glass tubes, quartz glass rods, quartz sheets, sapphire windows, calcium fluoride glass windows, infrared ultraviolet coatings, high-pressure resistant aluminosilicate glass window panels, quartz glass instruments, high borosilicate glass instruments, quartz crucibles, quartz gold-plated tubes, quartz heaters, quartz infrared heating tubes, far-infrared directional radiation heaters ultraviolet germicidal lamps and other special types of quartz glass products.

+86-0515-86223369

+86-0515-86223369  en

en English

English 日本語

日本語 Español

Español